Dinger's Aviation Pages

The Bristol Bombay.

An under-appreciated British transport/bomber aircraft of WW2.

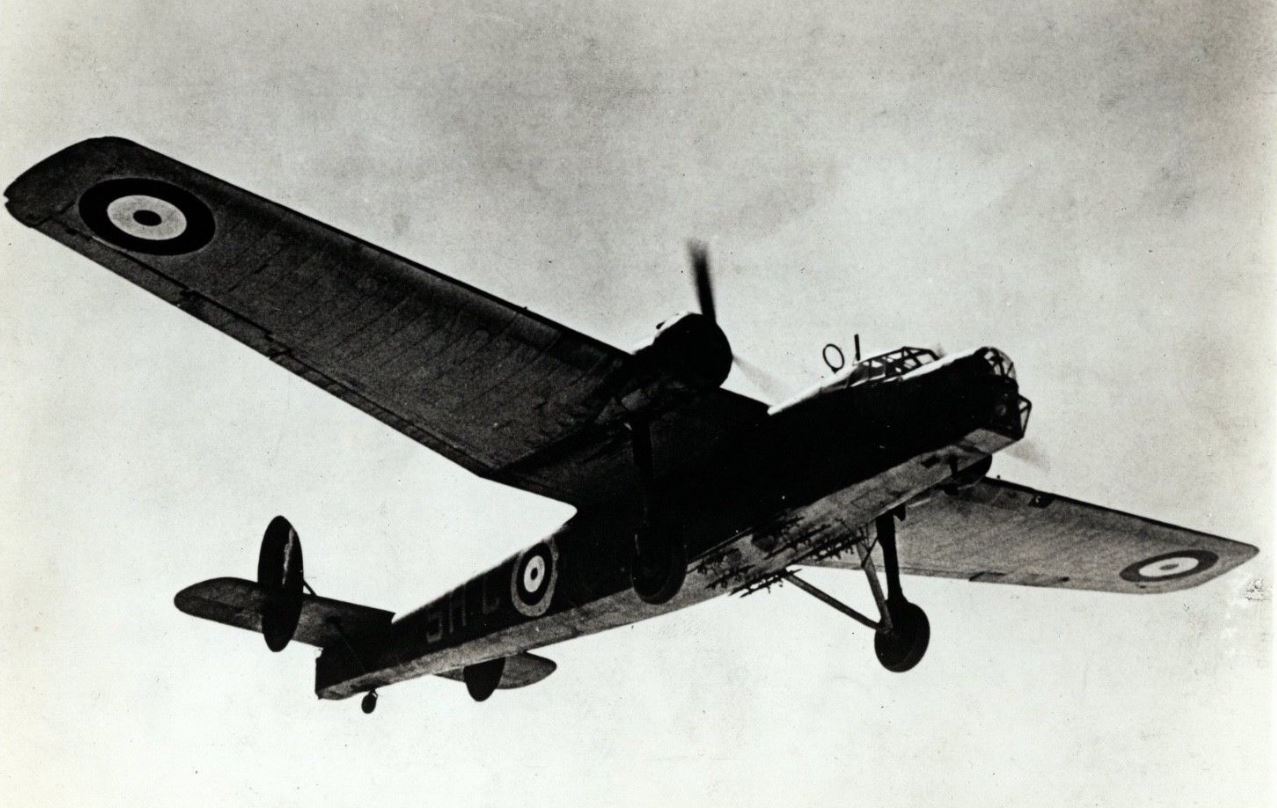

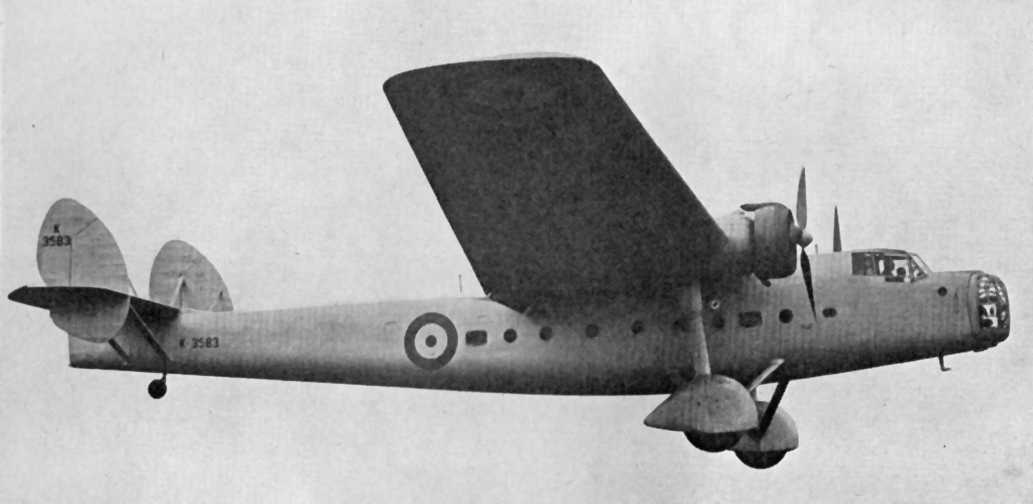

Bristol Bombay in flight, showing the under-fuselage racks for bombs or supply containers.

If you were asked to name the best transport aircraft of World War Two, chances are you would plump for either the American Douglas DC-3 (Dakota, C-47) or the German Junkers Ju52. There is no doubt that these aircraft were the most numerous transport types used in the war, and they both played an enormous role in the conflict. However, neither started out designed for the military transport role. Both were low-wing monoplanes principally built for economical use as airliners (although the Ju52 was adapted as a bomber, and was used as such during the Spanish Civil War). Neither was built with short take-off and landing as a primary concern. Since the war, high-wing military transport aircraft, usually loaded through a ramp at the rear, have proliferated. Aircraft such as the DHC-4 Caribou, DHC-5 Buffalo, C130 Hercules and Short C-23 Sherpa use this configuration. While smaller twin-engined "bush" aircraft also used the high-wing layout, often with fixed or semi-recessed undercarriages, such as the Twin Pioneer, Short Skyvan, DHC-6 Twin Otter, Britten-Norman Islander, Antanov AN-28, Dornier 228 and GAF Nomad.

The high-wing layout brings many advantages for a military transport aircraft. The fuselage sits closer to the ground, making loading and unloading easier. The pilot usually gets a better view back to the aircraft's wing-tips to better judge manoeuvreing around cramped airfields. High mounted engines can minimise the chance of someone walking into the propeller blades. There is less chance of the wing or flaps being damaged by debris from rough airstrips.

There was a British transport aircraft used in World War Two that had the high-wing layout that came to predominate post-war. It enjoyed a reputation for ruggedness and reliability. It was in many ways better suited to the military transport role than many of its contemporaries. Built with the latest all-metal monocoque techniques, it should have provided the British with an aircraft to rival the reputations of both the DC3 and Ju52 and yet it was built in only small quantities and is all but forgotten today. Yet its post-war derivative would go on to be an outstanding success story. The story of the Bristol Type 130 Bombay is a fascinating one.

Beginnings

In the mid-1920s, the Bristol Aeroplane company designed and built a large, twin-engined fighter to be armed with two 37 mm cannons to meet Air Ministry Specification 4/24. Called the Type 92 Bagshot, it was a high-wing monoplane design. First flying in June 1927, during testing the Bagshot's wing showed an alarming tendency to bend. The bending was so bad that it caused an "aileron reversal" effect, with the controls acting in reverse to that intended. This caused one of Bristol's engineers, Harry Pollard, to design a much more rigid and strong form of monoplane wing, one with no less than seven spars. The Air Ministry agreed to pay for the wing's construction and testing. The new wing was originally intended to be covered with fabric and have internal bracing, but the sudden availability of thin sheets of Alclad from the Northern Aluminium Company's new factory at Banbury in Oxfordshire made Pollard experiment with covering the wing with it. It was found that the metal covering enabled the internal diagonal bracing to be removed, with the metal skin of the wing absorbing the stresses instead, producing what was probably the first true British stressed skin wing design. Claims that the Short Silver Streak of 1920 had a stressed skin wing construction are incorrect, although it had a metal skinning to the wing the metal covering did not add to the strength of the wing (the Silver Streak did have an all-metal monocoque fuselage).

Bristol designed a three-engined transport aircraft (the Type 115) around the new wing to Specification C16/28. The Type 115 ended up being too small for the Air Ministry's vision, the competition for C16/28 ended up with prototypes for huge bomber/transports, the Gloster TC33, the Handley-Page HP43 and the Vickers Type 163, all of which ended up being too big and unwieldy for service. The Air Ministry were quick in realising that C16/28 had been a mistake, and even before the full testing of the prototypes built for it had been completed, issued a new specification, C26/31, for a more modest twin-engined bomber/transport.

The C26/31 Specification

The hybrid bomber/transport type was a class of aircraft prompted by the RAF's heavy commitment to policing duties in British mandates in the Middle East and on the borders of India. The Vickers Vernon, Victoria and Valentia family had served the RAF well from the early 1920s, rushing troops to trouble-spots and evacuating civilians in emergencies. The Valentia was used to bomb rebel tribal villages (usually preceded by the dropping of leaflets and aerial loudspeaker announcements). The RAF found this class of aircraft a valuable asset and other colonial powers, particularly the Italians, copied the concept. The C26/31 specification called for an aircraft that could replace the Vickers Valentia. The primary role was as a transport, it had to be able to carry at least 24 fully equipped troops or a load of fuel or water in tanks mounted in the fuselage. To make the aircraft self-supporting it should be able to load and accommodate three aircraft engines within the fuselage. If used for casualty evacuation provision for at least 10 stretcher cases should be provided. The ability to carry eight 250 lb (113 Kg) bombs and eight 24 lb (11 Kg) bombs was specified along with gun positions in the nose and tail for Lewis machine guns, each with 5 magazines of ammunition. The crew was to be composed of two pilots and two gunners. As per the normal RAF bomber protocol of the time, one pilot would fly the aircraft, while the other carried out the role of navigator and bomb aimer, swapping roles as required on long missions. The two gunners would be RAF tradesmen, usually one would be an engine mechanic and the other an airframe rigger, to provide the ability to do running repairs away from base. The aircraft had to be suitable for use in tropical conditions. The Air Ministry also specified that this new aircraft had to be a monoplane, an example of the Air Ministry forcing the pace toward monoplane designs, contrary to the myth that they distrusted monoplanes.

More than one commentator has made the point that the C26/31 specification seemed custom-made for the plot of the type of boy's adventure story popular between the wars. The officers "Biggles" and "Ginger" pilot their aircraft to rescue Princess Jelhi from the evil Khazi of Kalabar while the trusty lower-ranks "Chalky" and "Nobby" repair the aircraft just in time to take off and rake the pursuing Khazi's followers with Lewis-gun fire (the Bombay did end up featured in one "Biggles" Book by WE Johns; "Biggles Big Game Hunt" of 1948).

It should be noted that although the specification number C26/31 would normally indicate that it was issued in 1931 (the last two digits usually indicate the year of issue), C26/31 was put out to tender the following year, the 9th of April 1932 to be exact.

Five companies prepared designs for C26/31: Supermarine, Boulton Paul, Handley Page, Armstrong Whitworth and Bristol. Surprisingly, Vickers who had built the Vernon, Victoria and Valentia family, did not tender. Supermarine's Type 231 design was to be powered by twin Bristol Pegasus engines, but it was a biplane with the wing structure based on that of the Supermarine Stranraer flying boat. Being a biplane, it did not meet the Air Ministry requirement, which specified a monoplane. Likewise, Boulton Paul's type P69 was a tubby, enlarged version of their P64 biplane mail carrier and so also did not meet the specification. It is likely that both Supermarine and Boulton Paul designed their aircraft in the expectation that the other companies' attempts to build monoplanes would fail. Neither Supermarine's Type 231 nor Boulton Paul's Type P69 appear to have been formally tendered to the Air Ministry.

The Air Ministry ended up paying for the construction of three prototypes for C26/31. The Armstong Whitworth AW23 was a low-wing monoplane with a retractable undercarriage, looking like a fatter version of the later Whitley bomber, powered by two AW Tiger engines. The Handley Page HP51 was the earlier HP43 three-engined biplane converted to a twin-engined monoplane (it would later form the basis of the HP54 Harrow of which we will learn more later). The Bristol tender was their Type 130, a high-wing monoplane with fixed undercarriage with the wheels enclosed in large spats. It used the new 7-spar stressed-skin wing designed by Harry Pollard. The front Lewis gun was enclosed in a hydraulically powered turret while the rear gun position was originally just an opening with a Scarff ring. All three designs had twin, braced, rudders to accommodate the rear gunner position.

Armstrong Whitworth AW23 (left) and Handley Page HP51 (right) - The competitors to the Bristol 130.

The AW23, with its low-mounted wing and retracting undercarriage, looks the most "modern" design. Yet both it and the HP51 were structurally much more conservative than the Bristol 130. Both had substantial parts of the wings and most of their fuselages covered in fabric, whereas the Bristol 130 was the true modern aircraft, with both the wings and fuselage made from metal with only the control surfaces being fabric-covered (although the prototype had fabric-covered tailplane and rudders).

All three prototypes built for C26/31 first flew in 1935, the HP51 in May, both the AW23 and Bristol 130 in June. It seems the HP51 was never put forward to the Air Ministry for evaluation for the C26/31 contract, but instead was modified to serve as the trials aircraft for the later HP 54 Harrow design. The Harrow was a stop-gap medium bomber for the quick re-equipment of Bomber Command to face the growing threat from Germany and the Air Ministry wrote Specification B29/35 around the Harrow to cover its adoption. The AW23 had a serious disadvantage in using a pair of AW Tiger engines, an engine with a history of unreliability that blighted its use in such aircraft as early Whitley bombers, the Blackburn Shark and Armstrong Whitworth Ensign. Engine problems delayed the testing of the AW52 and it was quickly rejected, although it had given Armstrong Whitworth valuable data for the development of the Whitley bomber and was to go on to help with experiments that developed the idea of air-to-air refuelling.

The prototype Bristol 130

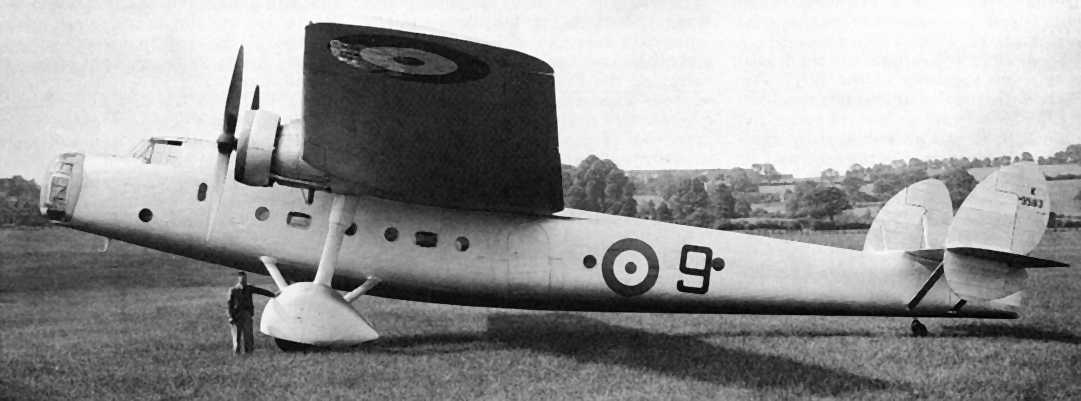

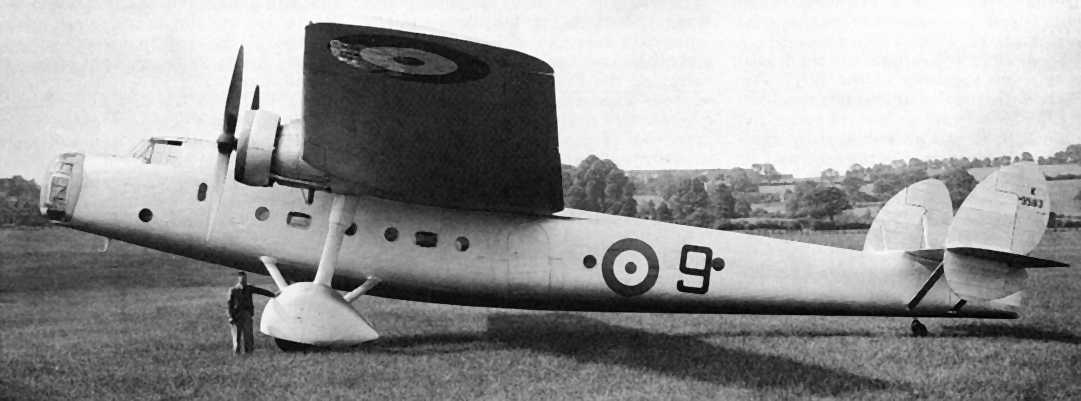

The prototype Bristol 130, registration number K3583, first flew on 23rd June 1935. Amazingly, within a few days, it was proudly on display at the annual RAF Hendon air display, wearing a large number "9" painted on the side so that visitors could identify it from the list of "new types" in the official printed programme. Then it went to the Aeroplane and Armament Experimental Establishment (A&AEE) at Martlesham Heath for a full evaluation.

The Type 130, shown in early configuration with "new types" number 9 on the starboard side of the nose.

Photos of the aircraft from the port side, show the number "9" painted further back on the fuselage.

Photos of the aircraft from the port side, show the number "9" painted further back on the fuselage.

Testing of the prototype revealed only minor issues that could be easily fixed, and the aircraft was praised for its flying qualities and the view from the cockpit. The stalling speed was only 42 mph (67.5 kph) which gave it a remarkable short-field performance for an aircraft of its size. The one thing that received major criticism was the front turret. Bristol had given the prototype an enclosed, fully rotating turret, traversed horizontally by hydraulic power (activated by the gunner's knees pushing against pads). The single Lewis gun was elevated and lowered manually through a slot that sealed itself with a zip fastener, Moving the gun moved the gunner's seat up and down to try to maintain line-of-sight to the target. The turret also incorporated a pop-out bomb-aiming window. The turret had many similarities to the one used in the Boulton Paul Overstrand bomber (except that the Boulton Paul turret was operated pneumatically rather than hydraulically). The official report said that aiming the gun was difficult and the turret was draughty. There was no way for the gunner to switch off the turret's rotating mechanism, so if the knee controls were touched accidentally while entering or exiting the cramped turret it would start to rotate, pinning the gunner in the entrance. It was recommended that if a better turret could not be developed, then a simpler manually operated gun mounting should be used. The A&AEE evaluation report also suggested that Bristol should provide more specialised tools, to be carried in the aircraft, to make accessing and replacing the engines quicker and easier.

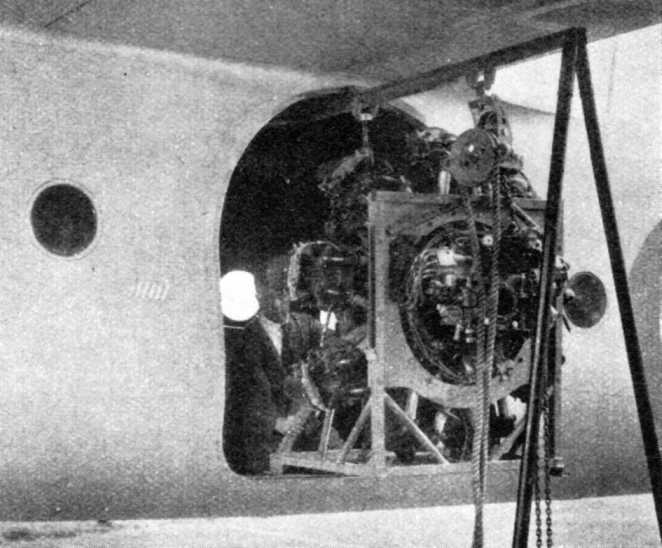

The turret of the prototype. Note the zip fastener running up the gun slot and the pop-out bomb-aimers window on the side of the turret. Also, note the two-bladed wooden fixed-pitch propeller originally fitted to the prototype.

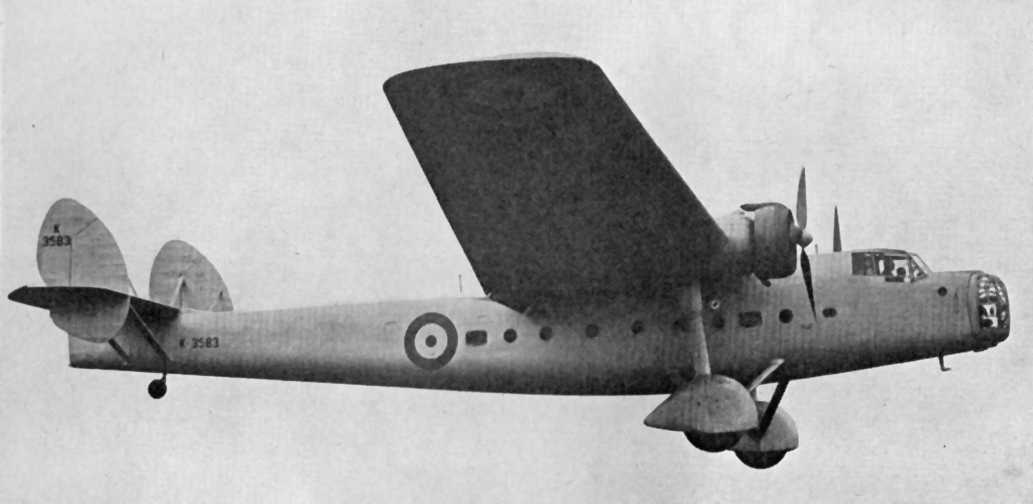

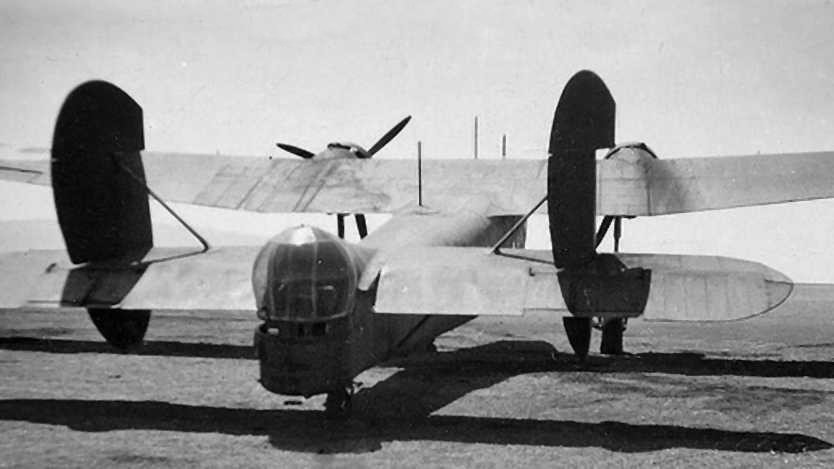

As originally evaluated, the prototype Type 130, K3583, had many differences compared to the later production machines. It was powered by two lower-powered 750 horsepower Bristol Pegasus IIIM.3 engines driving two-bladed fixed-pitch wooden propellers and the main undercarriage wheels were enclosed in spats. The tailplane and rudder assembly was fabric covered with the rudders being a different shape and with extra struts. It had just a simple opening for the tail-gunner with a Scarff-ring. The prototype was later modified to have three-bladed, metal Fairey-Reed propellers and the rear gunner's position was covered by a transparent cupola. Some sources imply that the prototype was bought up to near-production standard, with a modified tail assembly and the front and tail turrets used on the production aircraft, but no photograph I know of shows it in that configuration.

The Bristol Bombay prototype being inspected by Edward VIII at Martlesham on the 8th of July 1936.

The prototype K3583, shown with the later modifications: a cupola over the rear gunner's position and three-bladed propellers with central spinners. Notice the extra struts on the tailplane assembly compared to later production machines.

Another view of the Bombay prototype K3583.

Another view of the Bombay prototype K3583.

And the prototype K3583 was photographed a lot! As one of the new modern RAF aircraft, it appeared many times in newspapers and magazines in the late 1930s. In 1937 the prototype was even used to fly British Army staff to Berlin to witness German Army manoeuvres. With no actual production aircraft to see the form of the prototype was featured on postcards and on one widely distributed advertising poster for "Shell" fuels. This had the unfortunate effect of convincing many people that the Bombay had been in service with the RAF from the mid-1930s.

Contemporary postcard of Bristol Bombays. It shows all of them in the configuration of the prototype with serial numbers actually used by Hawker Hinds.

Striking painting for a Shell advertisement of the late 1930s, again showing three Bombays in the configuration of the prototype.

Sadly, the prototype came to grief in early February 1939. It experienced engine trouble but managed to pull off a perfect landing on a field on the edge of suburban North-East London. After the engine was fixed, the aircraft taxied to the far edge of the field to prepare for take-off but seems to have encountered some obstruction that caused the undercarriage to collapse. The aircraft was recovered to Bristol's Filton factory but it does not seem to have ever flown again. Full details at <this link>. The prototype does seem to have been kept in one piece at Filton for a number of years and visitors remember seeing it with the name "Josephine" painted on the nose. The last flight of the prototype was some three and a half years after it had first taken to the air, yet the first production aircraft had still not flown! What had been happening?

Delays in Production.

Testing of the prototype had been very successful and the Air Ministry seems to have decided very quickly that the Bristol Type 130 was an aircraft it wanted. However, a production order was slow in coming. With the growing threat of war in Europe, the pressing need was for bombers and fighters. The Ministry simply did not see a need for transport aircraft in a European war and the needs of air policing took a back-seat. The best illustration of this is what happened to Handley Page's design for the C26/31 specification. Handley Page redesigned it as a medium bomber with an internal bomb bay and Fraser-Nash nose and tail turrets. The Air Ministry wrote specification B29/35 around it (issued on the 5th December 1935), but significantly they had already issued a manufacturer's contract for 100 aircraft to Handley Page in August 1935, even before the specification was complete! The manufacturer's contract (435062/35) stressed the need for quick delivery. The Handley Page HP54 design was named the Harrow and the first one was flown in October 1936 and the entire production run of 100 aircraft had been delivered by the end of 1937, equipping five squadrons of Bomber Command. The Harrows were quickly replaced by the more capable Wellington, Hampden and Whitley and had passed out of front-line bomber service by the time Britain went to war, in September 1939. Thus, in the time-frame that it took to get the Bombay into production, the Harrow had gone into production, the whole production run had been delivered, it had seen widespread service and was on the verge of being retired from front-line duty!

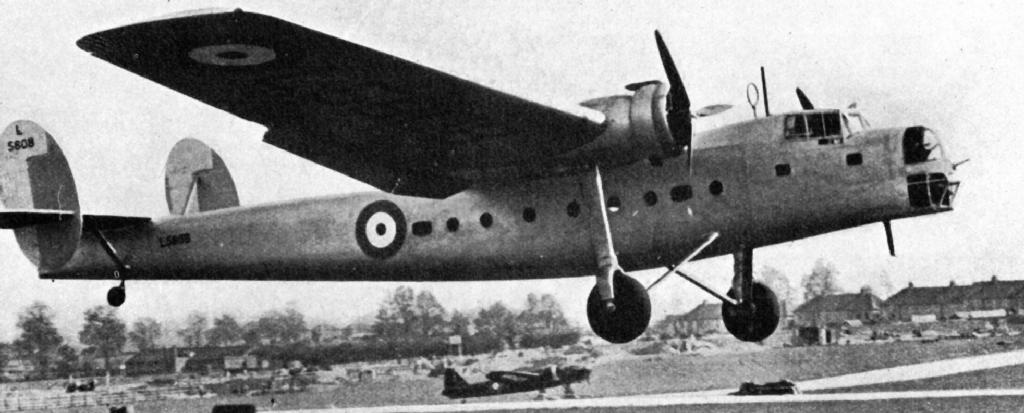

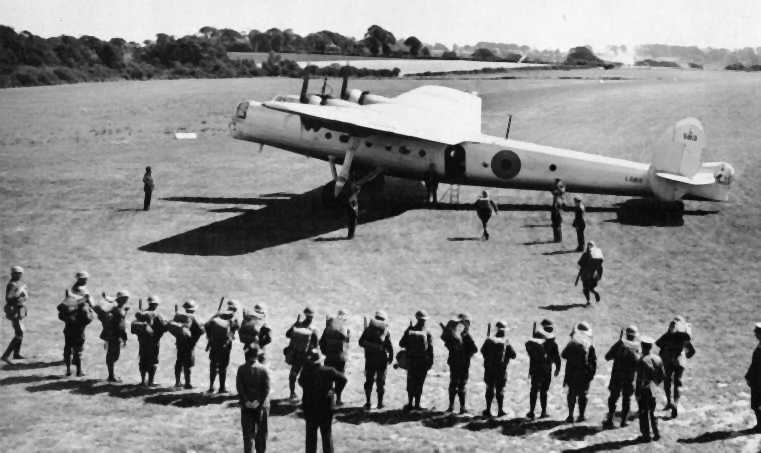

First production machine, L5808, coming in to land.

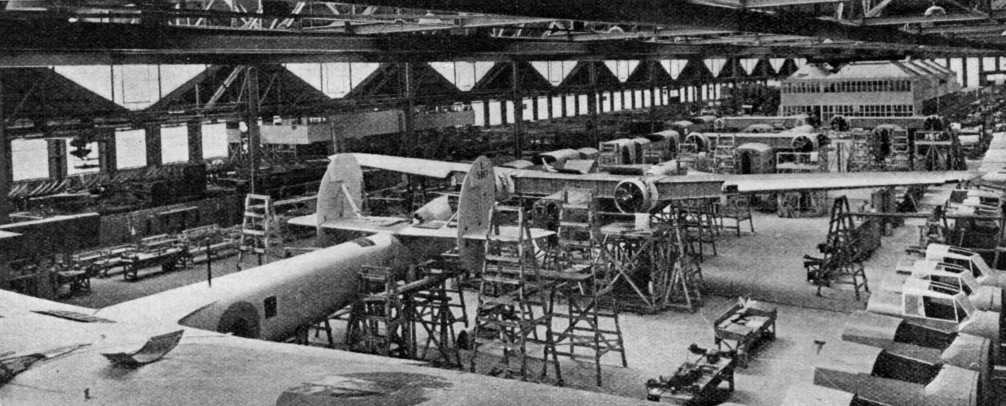

In the meantime, Bristol had been prompted by its lead in stressed skin design to produce a whole series of aircraft that used the new technology. Bristol's Type 133 fighter was the first Bristol design to actually take to the air (on 8th June 1934) with a wing built using the new structure. Numerous other designs followed, including the Type 142/143 small airliners which led to huge orders for the Type 142M "Blenheim" bomber, so there was no room at their Filton factory for producing the Bombay. It was eventually decided that the aircraft would be built at a new factory in the Sydenham suburb of Belfast in Northern Ireland. The factory and adjacent airfield were on land next to Belfast Harbour, some of it reclaimed from Belfast Lough by dumping refuse. The building of the factory was financed by the Air Ministry but its management was given over to a new company jointly owned by the Shorts aircraft company and the Harland and Wolff shipbuilders whose shipyards were nearby. So Bristol Type 130 production had to wait until the factory and its airfield were built. The Air Ministry issued two specifications to cover the type's production; 38/36 and 47/36. Even these were not actually issued on the dates you would assume from their numbers, 38/36 was issued in March 1937 and 47/36 was not issued until July 1937. These specifications detailed some changes from the prototype. Higher powered Pegasus XXII engines with three-bladed propellers were to be used, a new design of front and tail turret with Vickers "K" guns rather than the older Lewis gun. The ability to mount Vickers "K" guns in hatches on the side of the fuselage was also specified. 80 aircraft were ordered with serial numbers L5808-L5887 allocated (although only 50 would be built) and the name "Bombay Mk I" was adopted by the Air Ministry, while Bristol called the production aircraft "Type 130A" to distinguish them from the Type 130 prototype.

Bombay production underway inside the Sydenham factory.

The airfield at Sydenham was opened in March 1938 (it is now the George Best Belfast City Airport). A year later, the first production Bombay (L5808) flew (March 1939). The Bombay was not the only aircraft to be built at the new factory, the Handley Page Hereford (the Dagger-engined version of the Hampden) was also produced in parallel with the Bombay (the first Hereford produced at Sydenham flew in May 1939). The reason for the cut in production from 80 to 50 aircraft was probably due to a shortage of Bristol Pegasus engines. The last 18 Bombay airframes were put into storage until Pegasus engines became available. These engines were also used in Wellington and Hampden bombers and in August 1940 there was a backlog of 62 Wellingtons and 162 Hampden airframes in storage, awaiting engines; at this stage priority for Pegasus engines was given to Short Sunderland flying boats for use in the Battle of the Atlantic.

The first production Bombay (L5808) in flight.

L5811, the 4th production Bombay with the cranes of the Harland and Wolff Shipyard behind and behind them the skyline of the Black Mountain to the West of Belfast. This photo was often reproduced with the background airbrushed out by the wartime censor. This aircraft went on to serve with 216 Squadron in the Western Desert and was shot down by AA fire on 23rd January 1942. You can read the account of Jack Bell, the aircraft's radio operator who survived the crash, at <this link>

An open day and air display at the new airfield on the 29th July 1939, with throngs of people around a Bombay. To the right, behind the Bombay, is a Handley Page Hereford, 150 of which were produced at the factory (the last one was delivered in September 1940).

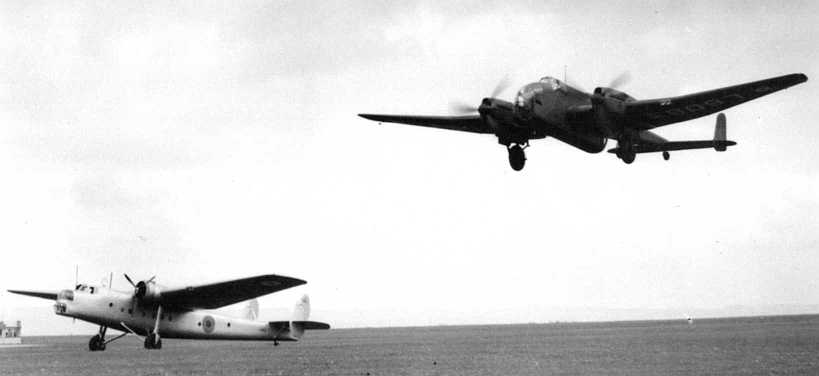

The two early products of the Belfast factory pictured together, the Bristol Bombay and the Handley Page Hereford.

The last Bombay airframe (without engines) off the production line (L5857) was delivered in June 1940. The Sydenham factory delivered the last of its initial production batch of one hundred Handley Page Herefords the same month (June), but then got a follow-on order for another fifty Herefords, the last of which was delivered at the end of September 1940. The Hereford was a failure, its high-revving, inline air cooled Napier Dagger engines proving very unreliable and the high-pitched scream they emitted made the Hereford very unpleasant to fly in. The factory then switched to building Short Stirling four-engined bombers. The Short Sunderland flying boat was also produced on the site, its position next to Belfast harbour being ideal for that purpose. The factory also reassembled aircraft shipped over from the USA into Belfast harbour.

The Bombay Described

So what exactly had the Air Ministry got for its money? For all the production delays, the Bombay was still quite advanced for the time. It was a strikingly large aircraft with a monocoque metal fuselage, and that amazingly strong, metal, multi-spar wing. The bracing of the tailplane had a slightly archaic look, but on the production Bombay, the tailplane and rudders were metal with only the control surfaces covered in fabric. The production Bombays did away with the undercarriage spats used on the prototype. They were powered by a pair of the highly reliable Bristol Pegasus XXII, 9 cylinder, medium supercharged, radial engines, giving 1,010 horsepower each for take-off and 890 horsepower each at 6,500 feet (1,980 metres). These were mated to Rotol, three-bladed, variable-pitch propellers. Some sources maintain that Fairey-Reed fixed-pitch propellers were used on production Bombays at first, as per the prototype and as per instructions in 47/36 that specified fixed-pitch propellers. However, an article in the 2nd of August 1939 edition of The Aeroplane magazine, clearly states that Rotol variable pitch propellers were being used.

A Bombay being serviced, somewhere in the Middle East. It is a very large aircraft, the largest aircraft that Bristol had built up to that point. You wouldn't want to fall off that wing! Note that the Rotol propellers do not have central spinners (unlike the three-bladed props fitted to the prototype).

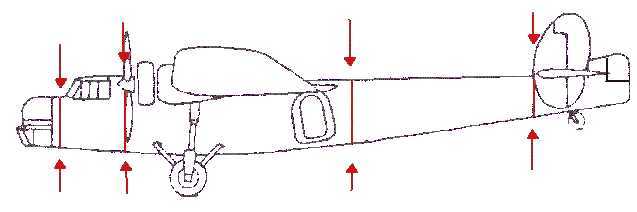

The Bombay had been designed for dispersed manufacture. The fuselage was composed of five units that could be built separately; the front turret, the cockpit and radio operators section, the passenger/cargo section, the rear fuselage section and then the tail section. The wing was in three parts, the inner wing with engines and the two outer wing assemblies.

Showing how the production Bombay fuselage was broken down into 5 units for manufacture.

The front and rear turrets and bomb-aimer's position had been completely redesigned. Both the front and rear turret had a single Vickers "K" gun that was mounted on its side. This was in a cylindrical bearing that was mounted in a horizontal slot that ran around the turret edge. The gun could be rotated around this slot by hydraulic power (provided by a pump on the starboard engine). The gun was still moved up and down vertically, through a somewhat limited arc, by manual action but the gunner did not actually hold the gun. Instead, the gunner sat some way back from the gun and manipulated it through a series of levers (looking like a cross between a pantograph and an anglepoise lamp). The gunner only had to handle the gun when changing the drum magazines. The gunner was provided with a reflector gunsight and a seat that rotated with the mechanism. The gunner sat in a transparent cupola that was fixed and did not rotate with the gun. The transparent perspex panels that made up the cupolas had no framing, they were riveted to each other. The rear gunner's position was provided with a mechanism whereby the entire cupola could be ejected to give a quick means of escape by parachute if required. These new turrets were in-house Bristol designs, given the designation type BII for the nose and BIII for the tail (the type BI was a dorsal turret with all-around rotation as used on the early Blenheims). Below the nose turret was a new layout for the bomb-aimer position, with large, flat perspex panels that gave an excellent view. Testing at A&AEE showed the new turrets to be a huge improvement on the prototype and the amount of draught was cut considerably. However, there was concern that the proximity of the "K" gun to the compass built into the bomb sight might cause the needle to demagnetise when the gun was fired. But this does not seem to have been an issue in service.

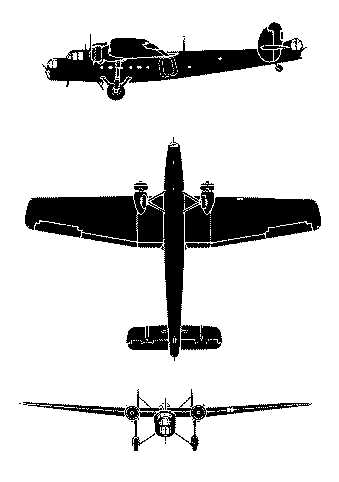

Showing the difference between the prototype Bombay (top) and a production Bombay (bottom). Note the upgrade from two to three-bladed propellers, the change in the front turret and the deletion of the spats covering the main wheels.

The front gun position of the Bombay. The fixed cupola is composed of perspex panels riveted to each other without framing. The Barr & Stroud Mk III reflector gunsight in front of the gunner is linked to the up-and-down movement of the gun via levers and the whole assembly is traversed by hydraulic power provided by a pump linked to the starboard engine. Although feeble against monoplane fighters such as the Bf109 it should be remembered that the turret's main use was to provide covering fire, like the door mounted guns on modern heavy-lift helicopters like the Chinook.

The rear turret of the Bombay. It was bulged to give a better all-around view. The entire cupola could be released by the gunner in the event of an emergency.

A close-up view of the Bombay's rear turret. The photo was taken inside a hangar (as you can see by the reflections in the perspex), but the Air Ministry censor has removed the background. You can see that the single machine gun is offset slightly from the middle of the turret ring. The lack of framing on the turret gives it a curious "soap bubble" appearance.

A close-up view of the Bombay's rear turret. The photo was taken inside a hangar (as you can see by the reflections in the perspex), but the Air Ministry censor has removed the background. You can see that the single machine gun is offset slightly from the middle of the turret ring. The lack of framing on the turret gives it a curious "soap bubble" appearance.

The front of the Bombay showing both the turret and the bomb-aimer's position.

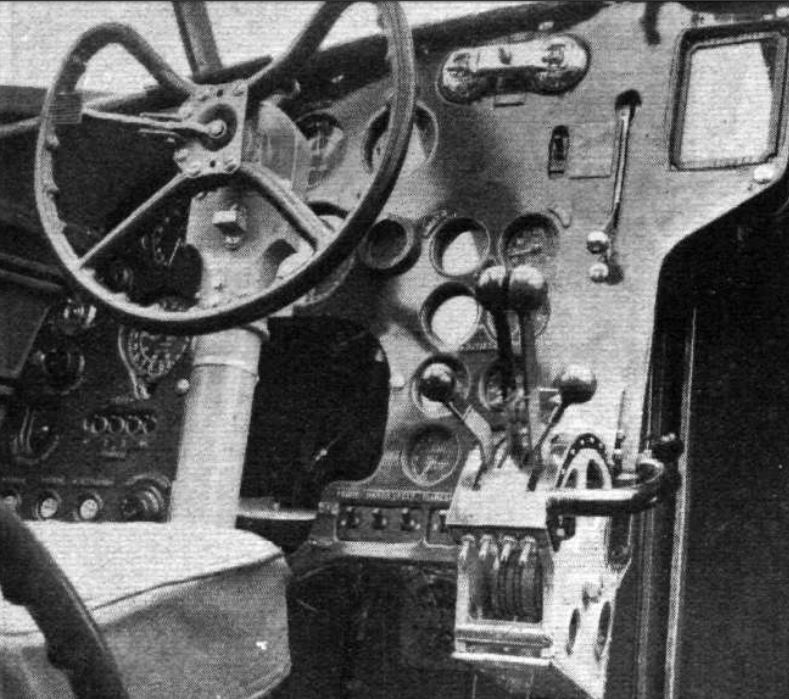

Despite what some online descriptions say, most Bombays were flown by a single pilot. There was a kit of parts that could be fitted to provide another set of controls for tuition purposes but it restricted entrance to the front turret and made getting into the pilot's position very awkward, records indicate it was only fitted to five aircraft on the production line (L5810, L5811, L5815, L5816 and L5825), and it may have been removed from some of them later in their service. The original specification for the Bombay mentions two pilots, but that was only because, in the early to mid-1930s, it had been standard practice for larger RAF aircraft to have two pilots on board, one of whom had the responsibility of being the navigator. By the end of the 1930s, the rapid expansion of the RAF meant there was a shortage of pilots and the luxury of having two pilots onboard large aircraft could no longer be afforded (unlike the USA, where a co-pilot was standard on most large aircraft). So navigation-trained Observers were carried instead. In 1942 the title of Navigator (first used in a limited manner in World War One) was reinstated. However, an examination of the histories of the squadrons that used the Bombays shows that the practice of carrying a second pilot to act as a navigator persisted within the Bombay fleet.

Bombay pilots instrument panel and control column.

The Bombay had a primitive autopilot to ease the tedium of long flights. There was a station for a radio operator behind and below the pilot with standard RAF radio sets together with a radio direction finding (DF) loop mounted on top of the fuselage, behind the cockpit. Two large aerial masts were positioned along the top of the fuselage and a trailing aerial wire could be deployed from a drum next to the radio operator's seat. To avoid the trailing aerial snagging on the bomb racks that could be fitted under the fuselage a raked-back tube supported by two thin struts was often fitted. The tube carried the aerial clear of the bomb racks. The normal position for the second-pilot/observer/navigator was a fold-down seat below and to the right of the pilot, from where they could also carry out the role of bomb-aimer (or also front-gunner if no dedicated gunner was carried). For celestial navigation there was a hatch with a sextant support rail for the purpose in the roof of the rear fuselage, adjacent to the beam gun-hatches. The Bombay had an Elsan "thunderbox" chemical toilet behind the door in the bulkhead at the rear of the passenger cabin.

The Bombay could carry up to 26 passengers who sat along the sides of the aircraft on fold-away bench type seats facing inwards. Above their heads were fold-down netting racks for baggage, similar to the type used on many railway carriages of the time. There were no seatbelts provided for the passengers. The role of loadmaster did not exist in the RAF during WW2 (they were not introduced until 1962), but it is clear that Bombays often carried volunteers from ground trades who could supervise the loading and unloading of freight, passengers and casualty-stretchers.

In the summer of 1939, the 6th Bombay off the production line (L5813) was used for a "photo opportunity" for the press to get pictures of troops using a Bombay. The resulting photos were then used throughout the early years of the war in newspaper and magazine articles.

The troops came from the Royal Ulster Rifles. They were loaded aboard the Bombay at Belfast and then flown over to the site of the photo-op, which was at RAF Benson in Oxfordshire. You can see the apprehensive young soldiers in the photo above. For most, it would have been the first time they had flown.

The soldiers disembarking. You can see they are wearing standard WW2 British webbing equipment but are not yet dressed in the battledress that was adopted by the British Army for WW2. They are still wearing WWI style puttees rather than WW2 style gaiters.

Another staged shot of soldiers jumping from a Bombay. They wear the same pre-war uniform with puttees, but it's a different aircraft (notice the difference in roundel style). In this photo, you can just about make out the outline of the rectangular hatch that could be opened to allow a machine gun to be mounted in a beam position (just to the right of the roundel). Notice that the door to the Bombay is itself contained within a larger panel. This could be removed altogether to permit the loading of large cargo, such as aero-engines. The small circular hatch on the right, below the circular porthole, is for an oblique photo-recce camera.

An alternative use for the Bombay was as an aerial ambulance. It could carry a maximum of 10 stretchers or a mix of stretcher cases and walking wounded.

Interior of a Bombay fitted out with 10 stretchers. See how the netting baggage racks have folded back against the fuselage sides. Notice the metal beam running the length of the cabin, from which heavy cargo could be suspended and easily moved into position before being secured.

Another role for the Bombay was the movement of heavy cargo. To make the Bombay fleet self-supporting, up to three Bristol Pegasus engines could be loaded.The large side cargo hatch was removed, a metal beam was bolted into place above the hatch which then mated with a beam that ran the length of the passenger compartment. The engines could then be suspended from the beam and slid along it into place within the fuselage, where they could be secured in place by retaining rods and chains. Once in place, the loading beam was removed and stowed and the cargo hatch put back.

Loading a Pegasus engine into a Bombay.

The same method was used to put in place up to three tanks for liquid. These could either be fuel, connected to the fuel system of the aircraft used to extend its range or either fuel or water to be shipped out to remote airstrips to replenish supplies.

Extra tanks loaded inside a Bombay. The box with the padded top in the bottom left of the picture functioned as an extra seat but held a large kit of tools inside for repairing the aircraft in an emergency. Also, notice the "door within a door" . The standard entry hatch hinged inwards but was mounted inside a larger, completely removable panel.

The Bombay had two large water tanks and an emergency ration pack in case of crashing in a remote desert location. It carried an extensive toolkit for carrying out running repairs. In case it was ever called upon to do photo-reconnaissance work it had fittings for cameras to be mounted to take pictures through two apertures in the underside of the fuselage, one vertical and the other oblique. It had chutes for signal flares (these could be operated by the pilot). The beam extension for loading heavy cargo and a metal ladder to provide easier access to the rear door were housed in the rear fuselage. The Pegasus engines could be started electrically from the cockpit. If the engines needed to be started manually, an extension shaft ran down the undercarriage legs to which a cranking handle (normally stowed in the rear fuselage) could be attached. Fuel was held in four wing tanks, with a combined capacity of 412 imperial gallons (1,873 litres). each additional fuselage tank held 180 imperial gallons (818 litres). This gave a maximum fuel load of 952 imperial gallons (4,327 litres).

The Bombay had an escape hatch in the floor next to the radio operators position. The top of the cockpit opened up to give an emergency exit route for the pilot. The larger windows in the passenger cabin could also be used as escape hatches (although access to them could be obstructed by stretchers if the Bombay was fitted out as an ambulance).

A Bombay being recovered after a forced landing. It is being towed through the streets of Holywood in Northern Ireland. You can just make out the emergency exit hatch; just forward of the front undercarriage struts.

The Bombay had a remarkably short takeoff and landing run for such a large aircraft. It had a landing distance of only 260 yards (238 metres) and it could clear a 50 foot (15.2 metres) obstacle after a takeoff run of only 470 yards (430 metres). Those are still-air figures, against a headwind a takeoff in a Bombay was described as, "like going up in a lift" (that's an elevator to anyone in the US).

One thing that is often not picked out on plans or models of the Bristol Bombay is the difference in fenestration between the port and starboard side of the Bombay's nose. The extra windows on the starboard side gave the pilot (who sat on the port side of the aircraft) a better all-round view.

Further Testing and a Fatal Flaw.

The first Bombay off the Sydenham production line was L5808. It first flew in March 1939 and was sent to the Aircraft and Armament Experimental Establishment (A&AEE) at Martlesham Heath for testing. During these tests, it was found that the fore-and-aft trim of the aircraft was very slow to set with the trim wheel. The pilot for some of these initial tests was Flt Sgt Cecil Higgins, who broke his arm in an unrelated accident and was taken off flying duties for a while. When he came to fly the aircraft again, on the 23rd of August 1939, the elevator trim control configuration had been changed to try to solve the trim issues but no one seemed to have told him. So he took off with it in the wrong position and the lack of strength in his arm probably stopped him from adjusting the trim in time to avoid a crash that killed him and the other two crew members on board. Two other Bombays, L5809 and L5812, were also sent to A&AEE, while L5811 went for brief trials with a front-line squadron (number 53 Squadron, then equipped with Blenheims) and L5810 was evaluated by the Central Flying School (CFS). L5812 was retained at A&AEE for some time to be used for trials of the new Mk IXA bombsight. Reports on the testing of these aircraft had some criticism of poor ergonomics of the cockpit layout, especially the location of the fuel cocks but the new turret arrangement was remarked on as being superior to the prototype. The major problem experienced was in trimming the aircraft fore-and-aft, and it was a change in the trimming system to try to address this that probably led to the crash of L5808. The small improvement to the trimming control still did not solve the issue completely, but it was deemed not bad enough to keep the Bombay from entering service and they started to be sent out to the Middle East. It seems the increase in weight of the tail due to the redesigned tail turret was probably the cause of the problem, and why it had not been evident on the prototype.

The trimming issue went on to affect the Bombay's service career. The change in trim caused by the weight of the gunner moving to the extreme tail of the aircraft was difficult for the pilot to trim out, even if he was warned it was going to happen. If a gunner moved to or from the tail without first warning the pilot it could cause the pilot real difficulty trying to retrim the aircraft. Under certain conditions of loading, if too much weight was put into the rear of the passenger compartment and then someone moved into the tail section, the aircraft would become uncontrollable. In light of this, it became common practice to not carry a gun in the rear turret. Instead, one or two bamboo sticks would be stuck protruding out of the rear turret slot, in the hope that it would deter an attack by enemy fighters. In service, passengers had to be warned not to move around the cabin, the later, fatal loss of one Bombay (L5822 in Egypt in September 1942) was blamed on two passengers wandering into the rear fuselage (their bodies were found there after the crash). After this incident, the door to the rear fuselage was often padlocked shut and passengers had to ask the crew's permission to use the thunderbox.

In Service

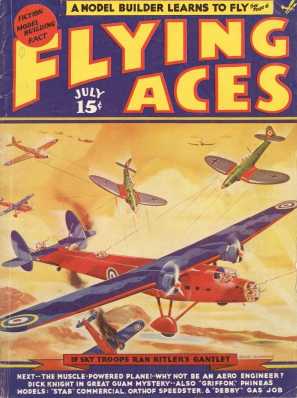

In the run up to the start of WW2, various military pundits speculated that British and French troops might be sent to aid Poland in the event of a German attack. One obvious (if foolhardy) way to do this would be to transport them across Germany in cargo aircraft, and the Bombay would have seemed the obvious choice. Hence this rather lurid cover to the American "Air Aces" magazine of July 1939, meant to illustrate one of the articles inside "If Sky Troops Ran Hitler's Gauntlet". The article suggested Bombays could be escorted across Germany by Fairey Battle bombers, that would clear a path by bombing German fighter aerodromes and warding off any fighters that managed to make it into the air! Many expectations for the nature of aerial warfare were shortly to be shattered! Notice it shows the Bombays in the configuration of the prototype, with spats and extra struts on the tailplane, albeit with an extra dorsal turret. When this magazine appeared the prototype was already disabled after an accident and only a few Bombays had been built and were still under trial.

When war broke out in September 1939, the Bombay was still not in service with any active RAF squadron. Some were allocated to No 10 Flying Training School at RAF Ternhill in Shropshire to train up pilots on the type, and one of these (L5818) was written off on the 10th October 1939 while making an emergency landing in poor weather. A small number of Bombays were then used by 271 Squadron, based at RAF Doncaster in South Yorkshire, to rush in reinforcements and then evacuate troops from France in the face of the German Blitzkrieg advances. 271 Squadron used them alongside a larger number of Handley Page HP Harrows converted to the troop-carrying and aerial ambulance role. One of 271 Squadron's Bombays (L5813) crashed in France on the 11th May 1940, killing three of the 12 passengers outright, while another later died of his wounds (the 3-man crew of the Bombay were unhurt). The squadron lost another Bombay (L5853) on the 29th of May when it crashed into a hill in poor visibility shortly after takeoff in an attempt to ferry much-needed anti-tank ammunition to France. The squadron continued to operate the small number of Bombays left in the UK, losing L5817 in a crash on 1st April 1941. Number 24 Squadron, a communications unit based at Northolt on the outskirts of London, also boasted a single Bombay (L5836) on its strength, but some of its aircrew logged flights in other Bombays during the emergency period of the evacuation from France and the Battle of Britain. In fact, Bombay L5852 was entirely crewed by members of 24 Squadron when it crashed on the 17th June 1940, killing all 5 on board, although the aircraft itself was not on the squadron's official strength. One remarkable story is that of a Bombay left abandoned, with a damaged tailwheel, on a French airfield at Nantes. Jean-Francois "Moses" Demozay, a French liaison officer with the RAF's No 1 Fighter Squadron, was ordered to destroy the aircraft left on the airfield after the rest of the squadron flew back to the UK. He persuaded the remaining personnel to do a temporary fix to the tailwheel and then flew it with 15 RAF groundcrew to England. This was even though he had limited flying experience and only in single-engined aircraft. He later went on to be an Ace, scoring 18 victories. A similar story can be found in a biography of Group Captain Frank "Chota" Carey, which tells of him being with three other "walking wounded" RAF personnel left behind in France who found an abandoned Bombay and flew it back to Britain.

Bombay in Flight.

In June 1940, there seems to have been some thought of three Bombays being given over to civilian use, with three civilian registration numbers (G-AFYM, G-AFYN and G-AFYO) being reserved for them. Just what civilian Bombays would be used for is a mystery. In any event, the registrations were never applied. Three years later, in August 1943, what was probably the last Bombay left in the UK (L5836) was loaned to BOAC for some reason but was scrapped shortly afterwards.

The major user of the Bristol Bombay was 216 Squadron based at Almaza (Heliopolis) in Egypt. Their first Bombays (L5815 and L5820) were flown out to Egypt in September 1939. The squadron went on to have 39 Bombays pass through their hands, the major part of the production run. Bombays were ferried out to Egypt via France and Malta during the first six months of the war. After the fall of France they had to fly via Gibraltar and Malta. The other major user of Bombays was number 117 Squadron, which formed in April 1941 when a flight of 4 Bombays from 216 Squadron were split off to join up with the Khartoum Communications Flight. 117 Squadron operated the Bombays alongside Italian aircraft, a captured Caproni Ca-133 and some Savio Marchetti SM79s supplied to Yugoslavia before the war and flown out to join the Allies. As the number of Italian aircraft diminished because of attrition the number of Bombays flying with the Squadron grew. Later in the war, 117 was reequipped with Lockheed Hudsons, after which the Khartoum Communications Flight was then reestablished, keeping some of the Bombays for a while. The other Middle East squadron sometimes reported to operate Bombays was number 267, which shared the Heliopolis airfield with 216 Squadron. Just how many Bombays 267 Squadron ever officially operated is uncertain, a inventory of their aircraft in July 1941 did not show any Bombays on strength (it used a miscellany of impressed civilian aircraft until reequipped with Hudsons in 1942). It seems likely that the Bombays all stayed on the official strength of 216 Squadron, but that crews from 267 also flew them when needed.

The wreck of a Bombay of 117 Squadron. It was damaged in a storm that swept through Khartoum on 21st April 1941. It seems this particular Bombay (L5826) was regarded as a rogue aircraft after it was involved in a series of unexplained losses of control and it had been left picketed out on the airfield at Khartoum stripped of its engines. Notice the beam gun hatch, open at the rear, and the top hatch that could be used for astro navigation. The tail assembly has become detached. The storm also destroyed the squadron's captured Caproni Ca 113, flipping it onto its back.

The Bombays proved a valuable asset in the Middle East. The aviation writer Bill Gunstone commented, "I doubt any batch of 50 aircraft accomplished more hard work than the Bombay." When war was declared by Italy, on the 10th June 1940, the Bombays of 216 Squadron were pressed into service as night bombers and started raids on Italian positions. The first took place on the night of 14th -15th June when a single Bombay bombed the harbour of Tobruk. With no dedicated night-fighters and very few searchlights, there was little opposition. The Bombay was sometimes used on nuisance raids, rather than dropping large bombs it would be loaded up with large numbers of small bombs. It could then cruise back and forward over its target for much of the night, with a bomb being manually fused and thrown out of the cargo door every few minutes, to deprive the Italians of sleep and keep their nerves on edge. Bombays continued to be used as bombers through the last half of 1940. The last Bombay bombing raid was on the 2nd January 1941.

Bombays in typical desert terrain.

With the Mediterranean closed to Allied convoys, supplies for Egypt had to come around the tip of Africa. To get urgent supplies and personnel across the continent more quickly an air route was pioneered. Usually referred to as the Takoradi Air Route, it started at Takoradi on the west coast of Africa in modern-day Ghana (then known as the Gold Coast) and went east across Nigeria, French Equitorial Africa to Khartoum in Sudan and then north to Egypt. At first, the Bombays were one of the few aircraft available to fly the route. However, the Bombays were so valuable in supporting the army and getting supplies to forward airfields, both in the Western Desert and in Sudan (for the war against Italian East Africa), that they were soon largely withdrawn from this role, their place taken by a motley collection of impressed civilian aircraft, although Bombays did continue to fly the route until at least 1942. Three Bombays are known to have been lost in crashes in Nigeria on the route, one at Lagos in April 1941(L5830) and two at Kano (L5823 and L5828). In 1942, one of the Bombays remaining with the Khartoum Communications Flight (L5809) made a forced landing in French Equitorial Africa and became bogged down. The crew were rescued by a Vickers Wellesley that managed to land nearby. Some weeks later, when the wet season had ended and the land dried out, a maintenance party got back to the Bombay and managed to dig it out of the baked mud and fly it out back to Khartoum.

Bristol Bombay, photo courtesy of Paul Lazell. His father served in the Western Desert.

The Bombay also found itself involved in the war in Greece and Crete, at first flying in British troops and supporting the RAF squadrons sent there, but later carrying out daring evacuation missions. According to one source¹, Bombays carried cargos that were 5,000 lbs (2268 kg) over their intended maximum weight during the evacuation from Greece. The Bombay is often credited with saving the Greek royal family from the advancing Germans, the true story is a bit more complex. The Greek royal family was evacuated from mainland Greece to Crete by a Sunderland flying boat. A week later most of the Royal party were then flown on to Alexandria in Egypt by a Bristol Bombay of 216 Squadron, but the King himself (George II) stayed behind on Crete. When the Germans invaded the island, the King had to trek over the central mountains before being rescued by the British destroyer HMS Decoy.

A Bombay on the airfield at Maleme in Crete. Notice the underside of the Bombay is painted black, a legacy of the night-bombing missions.

216 Squadron used Bombays to fly in supplies to Habbaniya, in Iraq, during the siege of April to May 1941. They also flew in troops from the Arab Legion and the Essex Regiment to secure the vital point "H4" landing ground, essential to the relief of Habbaniya.

Passengers in a Bristol Bombay. This view is looking forward. The radio operator's position was behind the bulkhead on the left. The radio operator sat facing forward with his radio equipment in front of him. The pilot was in front of and above the radio operator. You can see clear through to the front turret. Notice how some of the larger portholes have fastenings that enable them to be opened to serve as escape hatches.

During the siege of Tobruk, from April to December 1941, Bombays would fly hazardous night missions to take in urgently needed supplies and evacuate casualties. One source² says that during the siege of Bir Hakim, in June 1942, one Bombay even managed to land within its perimeter to bring urgently needed supplies to the Free French forces there (I've not been able to find confirmation of this in any descriptions of the land battle).

A Bombay runs up its engines.

One type of mission where the unique capabilities of the Bombay came into their own, was in supplying forward airfields. Because of their short-field capability and ability to carry fuselage-mounted tanks of both fuel and water, Bombays could bring in supplies in a way impossible for other types of aircraft. As the war progressed the RAF would sometimes fly fighters and ground-attack missions from rough airstrips behind enemy lines, or out in the desert on the southern flank. In July 1942 six Bombays flew some 200 miles behind enemy lines and landed in the desert to refuel Fairey Albacore torpedo bombers returning from an attack on an enemy convoy. All the Bombays returned safely. In December 1942, 216 Squadron Bombays were part of Operation Chocolate to disrupt Rommel's retreat from El Alamein by two squadrons of Hurricane fighters flying from an abandoned landing ground. These types of missions were not without their casualties though, on the 25th of September 1942 a raid by Luftwaffe Heinkel He III bombers caught six Bombays of 261 Squadron on the ground at Kufra Oasis in Southern Libya and destroyed three of them (L5833, L5843 and L5857). The Bombays had been there to support operations by Blenheim bombers of 15 Squadron SAAF.

L5857, Bombay "C" of 261 Squadron, one of those lost at the Kufra Oasis. On the original photo you can make out a bungee cord stretched down to the tailwheel, an unofficial modification carried out at Almaza (Heliopolis) to help keep the castoring tailwheel straight on take-off and landing. Also notice the raked-back rod protruding from the bottom of the front fuselage. This was a tube extension to the hole the trailing wire radio aerial could be extended through. It stopped the wire getting caught up in the bomb racks.

Loading stretchers onto a Bombay. Notice the machine gun mounted in the side hatch.

Loading stretchers onto a Bombay. Notice the machine gun mounted in the side hatch.

The most tragic (in terms of the number of lives lost) and notorious loss of a Bombay was on the 7th August 1942. A Bombay of 216 Squadron (L5814), tasked to pick up casualties from a forward landing ground, also took on board Lieutenant-General "Straffer" Gott, who had been appointed to be the new head of the British 8th Army only the day before. Shortly after taking off, the Bombay was attacked by German Messerschmitt Bf109 fighters and the Bombay crashed. General Gott and nine Army casualties were trapped in the fuselage and died. After the death of General Gott, Bernard Montgomery was put in charge of 8th Army instead. A very detailed article on the incident can be found on the 216 Squadron association website at <this link>.

Somewhere in the Middle East...

From February 1943, some Bombays were given to 1 Air Ambulance Unit (AAU) of the Royal Australian Air Force (RAAF) to supplement their de Havilland DH 86 aircraft. During 1943, 261 Squadron received Hudsons and Dakotas and their Bombays were released to No 1 AAU. By August 1943, 1 AAU was the last remaining unit flying the Bombay. The Bombays continued to perform sterling service, evacuating wounded from Sicily and mainland Italy. One crew alone ferried 6,000 casualties. By January 1944 the unit was down to only four Bombays. With the return of all Australian units to the Far East the unit was ordered to hand the aircraft back to the RAF, but before this could happen, one (L5820) was written off by a storm at Bari in Italy on the 11th February 1944. Bad weather meant the unit's remaining three Bombays had to be left at El Aouina in Tunisia.

In service with 1 AAU, Bombays were marked with prominent red crosses...

...including a large red cross on top of the wings. On one occasion these were mistaken for German markings leading to Bombay L5844 being damaged by Allied AA fire.

Lack of spares meant the Bombay was declared obsolete in August 1944 and the few that remained were broken up for scrap.

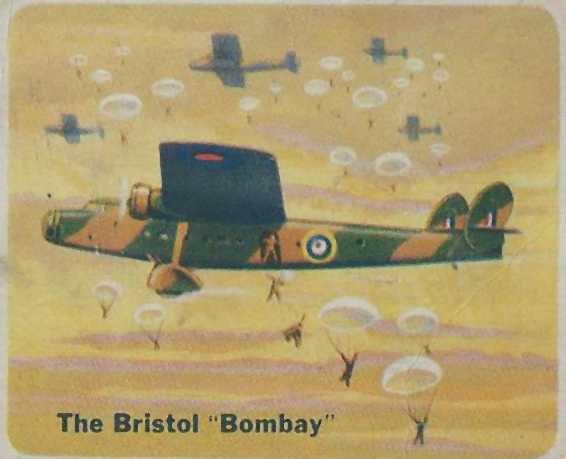

Bombays and Paratroops

The British adopted the use of paratroops only after observing the German's successful use of them in Norway and the Netherlands. At that stage in the war the RAF didn't have enough aircrew to man their fighters and bombers and so were reluctant to have too many dedicated transport squadrons in the UK.³ So, the newly formed British Airborne forces started out using the Armstong Whitworth Whitley bomber. Experiments were done with the paratroops jumping from the rear of the fuselage (the rear turret was removed). They initially adopted a method used in RAF displays at the annual RAF Hendon air shows. The paratroop would stand, facing forward, in the rear turret, then pull the ripcord of the parachute, which would stream behind the aircraft and pull the paratroop off. This method proved very slow and it would take multiple flights over a landing site to get all the parachutists out. Then they experimented with jumping from a hole in the floor of the Whitley (a hole initially designed to house a retractable ventral turret). Jumping through the hole was judged to be a much better option, although there was always the risk of thumping heads against the side of the hole when exiting, the dreaded "Whitley Kiss". The officer in charge of parachute training, Major John Rock, managed to get the loan of a Bombay aircraft in August 1940⁴. It had its large side cargo door removed and the beam used to load cargo was modified to be the attachment point for static-line parachutes (where the parachute is opened automatically by a line attached to the aircraft). The experiment was a great success and Major Rock, together with Admiral Keyes, then head of Combined Operations, campaigned to have Bombays made available for the airborne forces, if not for actual drops into enemy territory, then at least for training purposes. The RAF refused, and all available Bombays were sent to the Middle East. It's rather telling that all the descriptions of these events call the Bombay an "old aircraft of obsolete design", whereas, at this stage, no production Bombay was much more than a year old and it was in some ways a more modern design than the Whitley (the Whitley had two-thirds of its wing area covered by fabric). The airborne forces had to continue using the Whitley, which was far from ideal for the purpose; there was no room to stand up, the parachutists had to lay on the floor, usually huddled in sleeping bags to keep warm until the time of the drop, and then slither to the hole in the floor for the actual drop. The Whitley could only accommodate a maximum of 11 paratroops (usually only 8 or 9 were carried), only half that which a Bombay could carry in proper seating. Later in the war, the Whitley was replaced in the parachute-dropping role by the AW Albemarle (hardly an improvement) and the much superior American C-47 Dakota.

However, in the Middle East, Bombays were used to drop paratroops. In the Summer of 1941, the Special Air Service (SAS) was formed by David Stirling to perform commando-style strikes against the enemy by being dropped from the air. Five Bombays of 216 Squadron were allocated for the training of the force. Most descriptions of these events again describe the Bombay as old and antiquated. Furthermore, they describe the Bombay as "unsuitable for use with static line parachutes", this is despite the cargo beam in the Bombay being ideal as an attachment point for a static line rig and the successful experiments with it in the UK the year before. Rather, it seems there were simply no static-line parachutes available in the Middle East at the time, which forced the fledgling SAS to use ones with ripcords. The first SAS operation was a disaster. Launched on the night of the 17th-18th November 1941, it was an attempt to attack Axis airfields in the Western Desert in support of Operation Crusader to relieve the siege of Tobruk. To make the Germans think that the Bombays had flown from Malta, an extended flightplan to their targets out over the Mediterranean sea was to be used. To cover this extended range the five Bombays involved each had to have one of the additional 180-gallon fuel tanks mounted in the fuselage. This restricted the number of paratroops that could be carried. Two of the aircraft carried 12 SAS men, two carried 11 and one carried only 9. The raid was launched, against all advice, in the teeth of a fierce desert storm (the worst storm for many years). The aircraft had difficulty finding their targets and dropped the troops some distance from them. Many of the SAS men were injured on landing, dragged over rocks and sharp shrubs by the strong winds before they could release their parachutes. Many of their explosive charges detonated when the supply containers hit the ground and other supply containers were blown away by the storm. One Bombay (L5847) got lost, and miraculously managed to land in the desert at night. When dawn broke it found itself close to its intended target, a Luftwaffe airfield. After taking off it was quickly pursued by German fighters from that airfield and was shot down. Only 21 of the 55 SAS men involved returned to Allied lines. After this disastrous first mission, the SAS changed tactics and switched to driving behind enemy lines using trucks and Jeeps. There is a more detailed description of the SAS raid in this webpage on the Keymilitary website and also in the second half of this article on the Weapons and Warfare website.

Members of the SAS boarding a Bombay during training for their ill-fated first operation.

When the British launched a paratroop operation to blow up an aqueduct in Italy (Operation Colossus) and later the airborne raid to secure intelligence on German radar (Operation Biting) the wartime censors revealed little about how the operations were carried out or what type of aircraft were used.⁵ Some journalists padded out their articles about the raids with speculation that Bristol Bombays had perhaps been used. This was repeated in subsequent articles with the "perhaps" missed out. Even though the full story of both raids and the use of Whitleys in both of them was published by the British Government in 1943 ⁶, many post-war articles continued to say that the Bombay was used (for example, Putnam's "Bristol Aircraft Since 1910" 1995 reprint still maintained that Bombays were used in Operation Colossus).

This card, given away in boxes of crackers in the USA and Canada, adds to the mistaken idea that the Bombay was widely used for parachute dropping. Note the Bombay is represented with the wheel spats and turret of the prototype.

Afterwards and Afterthoughts

It is worth mentioning that the Handley Page Harrow bomber, which looks remarkably like the Bombay (so much so that you often see photos of them wrongly labelled as Bombays and vice versa) was adopted in limited numbers as a transport aircraft. Many were modified to do away with the front turret and replaced it with a much more streamlined, pointed nose. In this form they were known as "Sparrows". Used by 271 Squadron in the UK, they had nothing like the rough and tumble life of the Bombays (and there were much more spares for them at UK Maintenance Units). Like the Bombay, they ended up being used for aerial ambulance duties. Outlasting the Bombay in service, seven of them were destroyed at Evere in Belgium by German fighters taking part in the Bodenplatte attacks of January 1945. Five remained in service until May 1945.

Often mistaken for the Bristol Bombay, above is a photo of the Handley Page Harrow. Note the ridges on the fuselage, indicating it was covered with fabric.

The Bombay was in many ways the ideal transport aircraft for British use in World War Two. Of course, it lacked the speed and economy of the American DC3 / C-47 Dakota but in every respect it out-performed the German Junkers Ju 52. But British doctrine at the start of the war saw no major use for transport aircraft, unlike the Germans. So the Germans built over 4,800 Ju52s and had a fleet of between 400-500 available at the peak of their success, whereas the British cut short the production of the DH Flamingo, DH Albatross and AW Ensign airliners and cut the order for Bombays from 80 down to 50. You have to wonder if the Belfast Shorts & Harland factory would have been better off producing more Bombays, instead of 150 of the disastrous HP Hereford bombers.

Even while the war was raging, Bristol were thinking about how they could improve the Bombay, and it was hoped to provide a version for use in the Far East against the Japanese. That immensely strong wing was one of the Bombay's strong points, but its structure was also heavy, which took away from the disposable weight the aircraft could carry. So Bristol redesigned it and managed to keep the strength but reduce the number of spars down from 7 to 2, greatly decreasing its weight (Bristol's top stressman, Archibald Russell, had argued for a two-spar wing for the original Bombay). Mated to more powerful Bristol Hercules engines this would enable the aircraft to lift greater loads. So a larger cabin to accommodate more bulky cargo was designed with the twin pilot's cockpit positioned high up, enabling the cargo space to span from nose to tail. At first, a downward opening door in the nose was considered, to enable heavy loads to be hoisted up on a beam at the front of the aircraft to be then moved back into the cargo bay. This scheme was rejected in favour of clamshell doors that allowed vehicles to be driven up a ramp into the front of the aircraft. Keeping the Bombay's fixed, tailwheel undercarriage layout, but with a conventional single rudder, the new design first flew on 2nd December 1945. Called the Bristol Type 170 it was initially produced in two versions, the cargo version was known as the Bristol Freighter, while an all-passenger version was known as the Bristol Wayfarer. It was an outstanding success, 214 were built and they found use all over the world. They could carry either 36 troops with full equipment or 23 paratroops and their support equipment in containers or 28 stretchers. The cargo hold could accomodate a standard army 3 ton Bedford lorry, or a 25 pounder howitzer or a 17 pounder anti-tank gun or a Bofors 40mm AA gun. They were used by the Air Forces of Canada, Australia, New Zealand, Pakistan and Argentina. They did valuable service on the Berlin airlift; six Freighters did a total of 287 flights into the city, lifting 1,235 tons of freight, often bulky items that were impossible for other aircraft types. During the partition of India, one flew with 111 refugees on board. In Britain, they are best remembered for their regular car ferrying flights across the Channel, pioneered by Silver City Airways (a Freighter could carry two large cars). So popular was this service that some Freighters were given lengthened noses to accommodate an extra car, in which configuration they were known as "Superfreighters". Freighters were especially valued for supplying remote communities and mining operations, particularly in Canada where they continued to operate well into the 1990s.

Bristol Freighter unloading, showing the clamshell front doors. This sort of capability would have been welcomed in WW2.

RNZAF Bristol Freighter, showing the windows in the nose of some of the military versions to aid with supply dropping.

RNZAF Bristol Freighter, showing the windows in the nose of some of the military versions to aid with supply dropping.

A Bristol freighter of the RCAF transiting through Birmingham Airport in the UK. Many of the Canadian Freighters were modified with a weather radar mounted in a radome on the nose, above the clamshell doors.

A Superfreighter of Silver City Airways.

The Freighters were built at Bristol's Filton factory and a few were assembled under contract by Western Airways at Weston-Super-Mare.

Ironically, The Belfast factory that produced the Bristol Bombays later went on to build a successful family of aircraft very much in the mould of the Bombay. The Short Skyvan, Short 330 and 360 airliners and Short 23 and 23B military transports were all high-wing, twin-prop, twin-rudder aircraft with fixed or semi-retracting undercarriages, albeit with nosewheels rather than the Bombay's tailwheel. Tragically, the loss of one Short C-23B Sherpa, operated by the US National Guard, had echoes of the loading issue of the Bristol Bombay: see a description of the accident at <this link> on the Aviation Safety Net database. The factory also produced the massive Short Belfast military transport.

The Short C-23 Sherpa was built in the same factory site as the Bombay.

Bristol Bombay Specifications

Max speed: 192 mph (309 kph). Cruising speed 160 mph (257 kph)

Service ceiling: 25,000 ft (7,620 metres).

Range: 880 miles (1,420 km) extended up to 2,230 miles (3,590 km) by use of 3 extra fuel tanks mounted in the fuselage.

Span: 95ft 9 ins (29.18 metres). Length: 69 ft 3 ins (21.01 metres). Height: 19ft 6 ins (5.94 metres).

Empty weight: 13,800 lbs (6,260 Kg). Full weight: 20,000 lbs (9,072 kg).

Note that a table of performance figures for a production Bombay in an article in Air Britain Aeromilitaria magazine (see sources below) suggest different figures. Specifically a top speed of 183 mph (295 kph) at 10,000 feet (3,048 metres) and a service ceiling of only 21,000 feet (6,400 metres). However, these figures were at the maximum flying weight of 20,000 lbs (9,072 Kg).

Armament: Vickers K gun in both nose and tail positions (the gun in the tail was often not carried). Also, provision for a Vickers K to be mounted in hatches on both sides of the rear fuselage.

Up to eight 250 lb (113 kg) bombs or supply containers could be carried on external racks under the fuselage (a total of 2,000 lb / 904 Kg).

Alternative bombload was composed of numbers of small 2 Ib (0.9 kg) or larger 24 lb (11 kg) bombs carried internally and manually fused and thrown out the rear door on harassing "nuisance" night raids. Reports say the prototype (K3583) had racks for mounting small bombs inside the fuselage that could be swung out for dropping; this does not seem to have been carried over to production aircraft.

Engine: Bristol Pegasus XXII rated at a maximum 1,004 bhp (750 kw) at 2,600 rpm, using 87 Octane fuel. Driving Rotol three-bladed adjustable-pitch propellers.

Serial numbers: Prototype K3583. Production L5808-L5857

Max speed: 192 mph (309 kph). Cruising speed 160 mph (257 kph)

Service ceiling: 25,000 ft (7,620 metres).

Range: 880 miles (1,420 km) extended up to 2,230 miles (3,590 km) by use of 3 extra fuel tanks mounted in the fuselage.

Span: 95ft 9 ins (29.18 metres). Length: 69 ft 3 ins (21.01 metres). Height: 19ft 6 ins (5.94 metres).

Empty weight: 13,800 lbs (6,260 Kg). Full weight: 20,000 lbs (9,072 kg).

Note that a table of performance figures for a production Bombay in an article in Air Britain Aeromilitaria magazine (see sources below) suggest different figures. Specifically a top speed of 183 mph (295 kph) at 10,000 feet (3,048 metres) and a service ceiling of only 21,000 feet (6,400 metres). However, these figures were at the maximum flying weight of 20,000 lbs (9,072 Kg).

Armament: Vickers K gun in both nose and tail positions (the gun in the tail was often not carried). Also, provision for a Vickers K to be mounted in hatches on both sides of the rear fuselage.

Up to eight 250 lb (113 kg) bombs or supply containers could be carried on external racks under the fuselage (a total of 2,000 lb / 904 Kg).

Alternative bombload was composed of numbers of small 2 Ib (0.9 kg) or larger 24 lb (11 kg) bombs carried internally and manually fused and thrown out the rear door on harassing "nuisance" night raids. Reports say the prototype (K3583) had racks for mounting small bombs inside the fuselage that could be swung out for dropping; this does not seem to have been carried over to production aircraft.

Engine: Bristol Pegasus XXII rated at a maximum 1,004 bhp (750 kw) at 2,600 rpm, using 87 Octane fuel. Driving Rotol three-bladed adjustable-pitch propellers.

Serial numbers: Prototype K3583. Production L5808-L5857

Notes On Two Pre-War Planned Bombay Developments

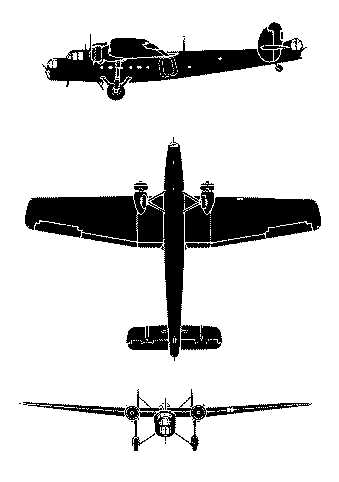

Type 137: In the 1930s, second-hand Fokker and Ford Trimotors started to be purchased by mining companies to ferry miners into remote sites and ship out high-value ore and gems. Seeing a potential civilian market for their Type 130 Bombay design, Bristol approached the Air Ministry to see if they would mind it being offered for sale to civilian concerns. The Air Ministry declined to make it available, and having put up the money to build the prototype, they had every right to do so. Bristol decided to tweak the design to better suit the civilian bush-country market, just enough so that it was no longer considered a Type 130. The first obvious step was to remove the front and tail turrets. This enabled them to give their new design a sleeker nose, but without a tail turret there was no longer any need for twin rudders, so a single fin was to be fitted. Mated to a slightly thinner fuselage this gave the aircraft a much more streamlined and attractive look. The most innovative part of the aircraft was the undercarriage. This was enclosed in a trouser fairing, but the wheels could be made to partially retract up into this fairing. This meant that once parked up on an airfield, the fuselage could be lowered so that it almost touched the ground. Then a whole section of the fuselage would open downward to form a ramp to enable easy loading without the need for any ramps or airstairs equipment on the airfield itself. The project never got beyond the design stage.

Bristol Type 137

Type 144: The "Bombay with a bomb bay". The basic Bombay design was upgraded to try to meet Specification B3/34 for a twin-engined bomber monoplane of stressed-skin construction. The Bombay wing was to be unchanged, but the undercarriage would be made retractable. The fuselage would be altered to accommodate an internal bomb bay and window beam gun positions would be fitted as standard. The design was offered with the same Pegasus engines as the Bombay, or with Perseus engines, which were expected to raise the top speed to 202 mph. The design study competed with ones from Boulton Paul (their P79 design), Fairey and Armstong Whitworth. It was the Armstrong Whitworth tender that won, even though most of its wing was covered in fabric and therefore did not strictly meet the specification.This winning design became the Whitley bomber.

Bristol Type 144

What If?

If the Bombay had stayed in production it might have seen much more widespread use. One would imagine it would have been of immense use in the Far East in the fight against the Japanese.

A Bombay in South East Asia Command (SEAC) colours.

Again, if the Bombay had remained in production it's possible to see it being adapted slightly in light of experience. In a purely transport role there turned out to be little use for gunners, so the turrets could be deleted, leaving a streamlined perspex nose for the navigator, still with a bomb-sight to do supply drops. Without a rear turret, a simplified single rudder could be adopted and the opportunity taken to fix the longitudinal trimming issue. The Bombay design, with both the nose and tail assemblies being built as separate units only joined together for final assembly, should have made such a development relatively easy.

A speculative "Bombay Mk II".

NOTES

¹ "The Book Of Bristol Aircraft" - See sources below.

² In various books and online articles I've consulted it says that there were attempts to parachute in medical supplies to Bir Hakim but that the contents were smashed on landing, some say the supplies were dropped from the bomb-racks of Hawker Hurricane fighters. The source for a Bombay landing at Bir Hakim is this page on the "History of War" website.

<Click here>

³ The British hoped to circumvent the need to build aircraft for transporting paratroops altogether by the use of gliders. The intention was that the glider could be towed behind any British bomber in service and that the paratroops would jump from the glider, with the glider returning to base with the bomber. The Slingsby T18 Hengist glider was designed with this tactic in mind, with slide-like chutes in the floor for dropping supply canisters and special folding doors for parachutists to be despatched from. See Aeroplane Monthly Magazine edition for November 1991, also the book "Slingsby Sailplanes" by Martin Simons.

⁴ Various histories of the development of Britain's Airborne Forces state that the Bombay was loaned in August 1940 and the story of its testing with static-line parachutes would only make sense in that timeframe. However, a list of service histories of Bombay aircraft compiled by Bruce Robertson for his 1964 article in "Air Pictorial", has Bombay L5836 being used by the Airborne Forces Experimental Establishment in November 1942. Documents in the public archive (AIR19/463) record a request by Admiral Keyes on the 8th August 1940 for an alternative to the Whitley. The response revealed that the Short Stirling and DH Albatross were unsuitable and that there was only three Bombays in the UK in flying condition, although there were another 18 airframes awaiting engines, priority in supply of Pegasus engines being given to Short Sunderland flying -boats. A precis of the correspondence is in the "Out of the Archive" feature in the Autumn 1999 edition of Air-Britain Aeromilitaria magazine (see sources below).

⁵ The Italians captured all the paratroops involved in Operation Colossus and were very keen to discover what type of aircraft they had jumped from. Under interrogation, the British captives told them the aircraft was a new type; the "Heinz 57" fitted with "Crosse and Blackwell" engines . Apparently, their Italian interrogators were satisfied with the answer! See "The Guinea Pigs - Britain's First Parachute Raid" by Raymond Foxall, ISBN-10 : 0709007620.

⁶ The HMSO booklet "Combined Operations 1940-1942", published in 1943, contained an extensive overview of the operations and the use of AW Whitley aircraft to drop the paratroops.

LINKS

List of Bristol Bombay losses on the Aviation safety website.

Fate of Bristol 130 prototype on Aviation Safety website

Fate of first production Bombay on Aviation Safety website.

Footage of Bristol Bombays on YouTube.

Another YouTube video with a brief view of Bombays in the Western Desert

Another YouTube video with brief view of a Bombay

Ed Nash's "Forgotten Aircraft" Youtube video on the Bombay.

In-depth article on the shooting down of the Bombay that killed General Gott.

Another article on the shooting down of the Bombay that killed General Gott.

Details of a Bristol Bombay that crashed near Gibraltar

Extensive details of Bristol Bombays flown by No 1 Air Ambulance Unit RAAF

Bristol Bombay photos in the Air Britain Collection

Some excellent side-profiles of Bombay colour schemes on the "Warmachinesdrawn" blog.

SOURCES

The Aeroplane Magazine of 2nd August 1939 contained an article describing the structure of the Bombay, along with James Clark's magnificent cutaway drawing.

"The Bombay - Pegasus Draught, Bristol Dray": An article by Rupert Cooling in Issue 18 (April 1982) of Air Enthusiast Magazine. It has an even more detailed cutaway drawing by Aviagraphica.

A letter and photographs from Peter HT Green in the "Talkback" column of Air Enthusiast Magazine number 25 (Aug 1984) with a following reply and photograph from Sdn Ldr DW Warne in the next edition (number 26, December 1984).

Correspondence with Stephen Bennett, who's father, Dennis Bennett, was one of the RAF groundcrew flown back to the UK in a Bombay by Jean-Francois "Moses" Demozay.