Dinger's Aviation Pages

The Bristol Type 133

Prototype Monoplane Fighter

and Specification F7/30.

Being first doesn't always guarantee success.

The Bristol Type 133 was the first British fighter aircraft to feature the combination of a monoplane wing of stressed-skin construction, an enclosed cockpit and retracting undercarriage; yet it is all but forgotten today.

In the late 1920s Harry Pollard, an engineer at the Bristol Aircraft Company, was tasked with designing a strong monoplane wing to replace that used on Bristol's Type 92 Bagshot twin-engined fighter prototype. The Bagshot had suffered from alarming flexing of its wings during flight and a much stronger, stiffer wing was required. The Bagshot was cancelled but research into a stronger wing continued with the aim of using it on Bristol's Type 155 three-engined transport aircraft project; when that, in turn, was cancelled the new wing design was modified to be suitable for the Bristol Type 130 high-wing monoplane bomber-transport "Bombay". The wing had no less than seven spars for strength with internal wire bracing and was originally intended to be covered in fabric. The sudden availability of thin sheets of Alclad (duralumin with a surface layer of pure aluminium that resists corrosion) caused Harry Pollock to experiment with using it to cover his new wing design. The multiple spars combined with the metal covering produced a multi-cellular stressed-skin structure, where the metal skin contributed to the strength of the wing, allowing the internal bracing to be removed. Thus Pollard had independently, and almost by accident, invented the stressed-skin structure that would come to predominate in aircraft construction. It would seem this development was completely independent of the same discovery being made in the USA (the Northrop Alpha small airliner of 1930 is usually credited with being the first US aircraft with stressed-skin construction). Don't confuse merely covering the wing of an aircraft with metal with stressed-skin construction. A few aircraft in WW1 and lots of aircraft in the 1920s had metal-covered wings, but the metal covering did not add to the strength of the wing. Claims that the Short Silver Streak of 1920 was the first British all stressed-skin aircraft do not stand up to scrutiny (its fuselage was a metal monocoque but the wings were of traditional construction, just covered in duralumin). The Rohrbach wing structure, as used on the Beardmore Inflexible, did have a central stressed-skin section, albeit it was very heavy.

Even before the prototype Bristol Bombay had been built, Bristols looked at ways they could capitalise on this sudden lead in technology. Air Ministry specification F7/30, calling for a new fighter aircraft for the RAF to replace the Bristol Bulldog, must have seemed the ideal project to use the new stressed-skin wing construction.

The Myths of F7/30

Up until the late 1980s, the history of Air Ministry specifications was largely written by the British aviation industry itself or by information its sales and public relations departments passed on to aviation writers and journalists. This naturally painted the aviation companies in a good light while often denigrating, or even ridiculing, the Air Ministry. The official specifications themselves remained classified and the senior officers and civil servants involved in drawing up the specifications were not able to write or talk on the subject, restricted as they were by the Official Secrets Act. One officer who did break ranks was Air Marshall Sir Ralph Sorley (in an article in the Times newspaper in 1957) but he only talked about the adoption of increased numbers of machine guns and he rather bigged up his own involvement and without access to official files he remembered dates out of sequence. This has led to many misunderstandings and myths about Air Ministry policy in general but the F7/30 specification seems to have been the subject of particular misrepresentation, all repeated in numerous books from the mid-1940s onwards. The various Putnam titles on the products of British aircraft companies are particular offenders.

The myths of the F7/30 in their broadest form consist of the following points:

1. That the specification called for a top speed of at least 250 mph (402 kph).

2. That the specification called for the use of the Rolls Royce Goshawk engine (or expressed a strong preference for it).

3. That the Air Ministry distrusted monoplane designs and was prejudiced against them.

4. That F7/30 was abandoned and replaced by "F14/35" and it was that specification that was "won" by the Gloster Gladiator.

Starting from as early as 1967 many of the documents in government archives that dealt with specification F7/30 began to be available; analysis of these documents throws an entirely different light on the specification. The author Colin Sinnott wrote an excellent outline of these discrepancies in his 2001 book "The RAF and Aircraft Design - 1923-1939" but it was published by Frank Cass, a rather niche publishing house and it retailed for quite a high price, so it did not get a wide readership at the time (it is now available as a Kindle e-book, but is still relatively expensive). Sinnot's analysis of the documents and a viewing of the actual specification document¹ reveals the following points about F7/30:

1. There was never a minimum speed of 250 mph (402 kph) specified. Instead, the minimum speed was initially to be a rather conservative 195 mph (314 kph). Consideration was then given to it being raised to 215 mph (349 kph) but then it was revised down again to 195mph for the final release of the specification. This is less than the 200 mph (322 kph) specified in the earlier F20/27 specification for an "interceptor" which led to the Hawker Fury. This stresses that the F7/30 specification was for a replacement for the Bristol Bulldog "zone fighter" which only had a top speed of 178 mph (286 kph). The F7/30 specification was formulated to produce an aircraft that combined the roles of both interceptor and zone fighter, uniting the high speed, fast climb and good view from the cockpit of the interceptor class with the ability to fly and fight at night and carry a two-way radio of the zone fighter. It was the capability to land in a small airfield at night (the initial specification draft was for a landing speed of 50 mph but this was later raised to 60 mph) that was the biggest barrier to high speed. It was hard for designers to achieve both high maximum speed and low stalling speed without the use of flaps or slots, which were then in their infancy.

2. There was never a stipulation that the Rolls Royce Goshawk engine should be used. The requirement was only that an approved British-manufactured engine be fitted. Ironically, during the meetings about the F7/30 specification, Air Marshall Dowding who was then responsible for research and supply, asked that the Goshawk and any other inline engine be excluded from use. He was keen that support be given to the radial engines of Bristols and Armstrong Siddeley (the latest versions of the Bristol Mercury along with the Armstrong Siddeley Panther and Hyena engines). It may be that the majority of manufacturers who choose to use the Goshawk did so because it initially seemed to offer more power than either the Mercury or Panther but also simply because Rolls Royce made it easier for them to get their hands on the engine. Manufacturers who were chosen to have their prototypes fully financed by the Air Ministry had the engine provided free of charge, while even those companies building prototypes with their own money, the so-called "Private Ventures" (PVs) seem to have been offered loans of Goshawks at very cheap rates or had it paid for by the Air Ministry (as in the case of the Bristol Type 123). It should be remembered that Bristols and the Armstrong Whitworth/Siddeley companies were in direct competition with the other manufacturers (this was before Hawkers combined with both Gloster and Armstrong Whitworth to form the Hawker Siddeley group) so hardly likely to give them the best terms for the purchase or loan of their latest engines. Also, the Goshawk was seen as a safe bet and considered to already be a solid, reliable engine, being based on the proven Kestrel engine (it was originally called the Kestrel Mk IV). Meanwhile, the Armstrong Siddeley Panther and Hyena were all at an early stage of development (the Panther had a troubled history and saw only limited production while the Hyena was an outright failure). Development of the production Bristol Mercury engine seemed to be stalled at under 600 horsepower. A special Bristol Mercury racing engine of 800 hp had powered the Short Crusader monoplane floatplane in the Schneider Trophy races but had not been powerful enough to compete against the inline powerplants with skin surface cooling of Rolls Royce and the Italians. So there was a definite "fad" for inline engines in the early 1930s. It may be that Bristols relished the chance of getting their hands on a Goshawk engine so that their engine division could give it a close examination. Those designers who chose to use the Goshawk seem to have seriously underestimated the problems of incorporating its evaporative cooling system, with the associated condenser tanks, into their airframes.

3. The myth of Air Ministry prejudice against monoplanes is worthy of an article in its own right (<click here for one>). It has its seeds in a misunderstanding of events before World War One when the Royal Flying Corp briefly suspended all flying in monoplanes for 5 months due to a spate of accidents in them.² In terms of the F7/30 specification, the minutes of the meetings show that the Air Ministry sincerely hoped that it would elicit monoplane designs in response. In fact, when the new specification was first discussed the first proposal was that it should specifically call for a low-wing monoplane, but this was rejected in the hope that even more radical designs such as tailless configurations (like the Pterodactyl designs of Professor Hill at Westlands) and monoplane pusher configurations (to give a better view for the pilot) would be forthcoming. The records show that they considered any tractor biplane designs to be "lazy" responses from the industry. As it is, in the very first paragraph of the F7/30 specification, designers are asked to consider the advantages offered by low-wing monoplanes.

4. Some articles, for example Ken Ellis's article on the Schneider races in the December 2018 edition of Flypast magazine, suggest that F7/30 was abandoned, to be replaced by "F14/35". This is not true, it stems from the misleading way the Air Ministry specification system worked. The Ministry issued specifications for three different reasons. 1. The setting out of the requirements for an aircraft open to tender to all the British aircraft industry (or selected manufacturers). In essence a competition; that was what F7/30 was. 2. The production of a prototype (or series of prototypes) of a specific design by a specific manufacturer. An example of such a specification is F7/34 for the prototype Spitfire. 3. Lastly, are production specifications issued to manufacturers of the aircraft selected for production by the first two specification types, or aircraft ordered "off the drawing board" without competitive selection or production of a prototype for initial testing. Specification 14/35 (it didn't have the prefix "F") was one of this third type. It was simply an order to produce the Gloster Gladiator, already chosen for F7/30, without any additional selection process.

One other misunderstanding about F7/30 is the assumption that it was issued in 1930 (the last number in a specification usually indicates the year it was issued). In fact, its release was deliberately delayed until October 1931 because of news from the USA of the development of retractable undercarriages, NACA cowlings and metal propellers, all technologies that the Air Ministry thought could be exploited in the new designs. The Air Ministry also wanted to see how the new Hawker Fury and Demon fighters performed during RAF air exercises in the late Summer of 1931. There was also the issue that the new six-gun Gloster SS19A fighter (later developed into the Gloster Gauntlet), seemed to already exceed many of the design requirements of F7/30 except for the view for the pilot.

It was the Gloster Gladiator that "won" the F7/30 order but what is often overlooked is that its predecessor, the Gloster Gauntlet, was ordered to start replacing Bristol Bulldogs and performed both the interceptor and zone fighter roles, including flying at night, so effectively pulling the rug from under the F7/30 specification. The Gladiator was the logical development of the Gauntlet, using the increasing power of the later marks of Mercury engine to boost top speed to 250 mph (402 kph) while using flaps to keep the landing speed low. It may be that the myth of 250 mph being written into the F7/30 specification could stem from the Air Ministry informally telling the aircraft manufacturers, prior to the testing of their prototypes, that they needed to beat the Gladiator's performance to stand a chance of winning an order.

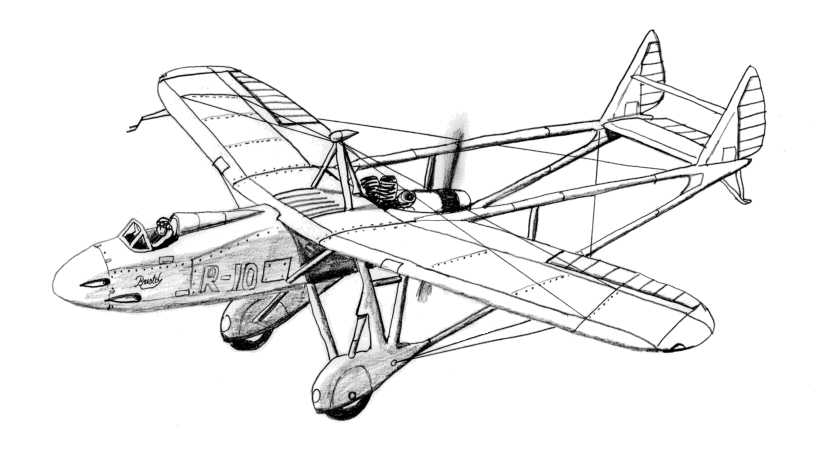

Bristol was prodigious in its response to F7/30, producing numerous different design studies. This was natural, since the winner would replace Bristol's earlier Bulldog design in squadron service and the company desperately needed more orders to keep in business. Seeing that the Air Ministry was keen to explore pusher monoplanes one of their designs, the Type 129, was just that. However, even though it was a monoplane it had a weirdly anachronistic look. Its wings were not cantilever and had to be braced by wires that went up to a pylon above the fuselage and to the large, fixed, spatted undercarriage that was part of the strutted structure that supported the twin-boom tail. It had four Vickers machine guns in the nose and was to be powered by a Bristol Mercury engine. Development of the Type 129 seems to have been dropped fairly early.

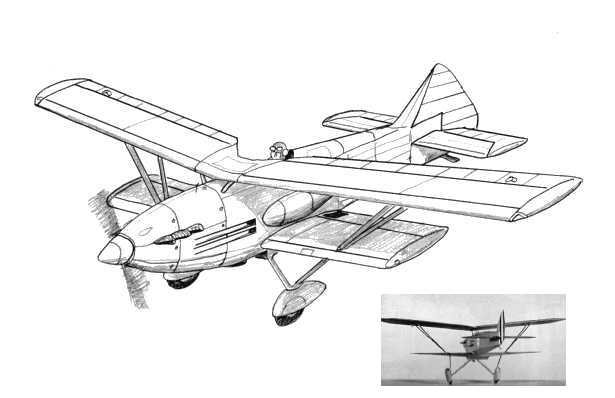

The anachronistic looking Bristol 129 pusher design. It goes to show that just because an aircraft is a monoplane, it doesn't make it a modern aircraft. Notice the bracing wires needed to support the wings. You've to wonder how the pilot would get into the cockpit.

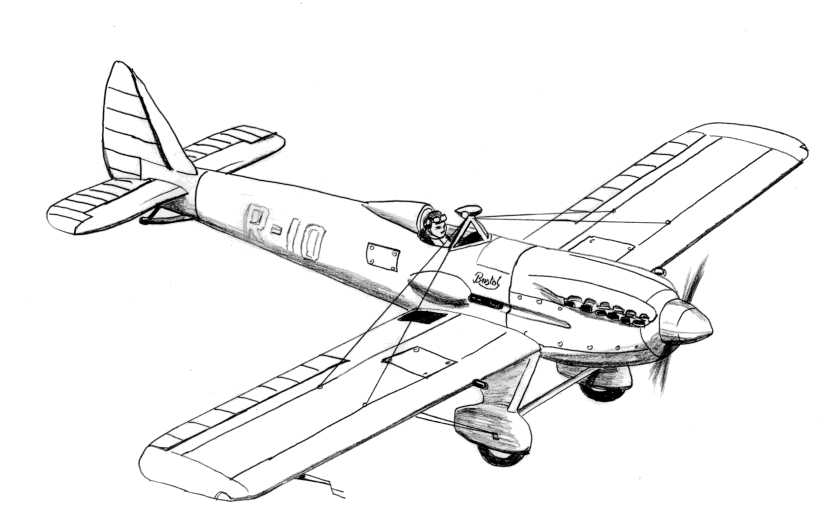

At the same time they had been looking into two similar-looking designs, the Type 127 and 128. They were both low-wing monoplanes with fixed, spatted undercarriages, but like the Type 129, the wings were not built as full cantilever structures and therefore needed bracing wires from pylons above the fuselage and to the undercarriage. Both designs carried two Vickers guns in the fuselage and two Lewis guns, one in each wing. The Type 127 was designed to be powered by the Rolls Royce Goshawk engine, while the Type 129 had Bristol's own Mercury radial engine. The Type 128 looked very similar to Vickers' Type 159 "Jockey" except that the Vickers design had a more advanced structure with cantilever wings skinned in metal that needed no bracing, being based on the construction methods of Michel Wibault. The 127 and 128 got no further than being paper design studies.

The Goshawk powered Type 127.

The radial Mercury powered Type 128.

All of these first three designs had been the work of Frank Barnwell, Bristol's long-standing chief designer who had made his name with the famous Bristol Fighter of WWI. The company also had a formative biplane design (the Type 123) by its other designer, Leslie Frise. It was Frise who had been responsible for most of the design of the Bulldog (although, being nominal chief designer, Barnwell is usually credited as the Bulldog's designer). The Type 123 seems to have started off as a tentative outline for an earlier specification (either F10/27 or F20/27), and was dusted off and updated to meet F7/30. Despite being a biplane, the updated Type 123 design had some innovative features that promised to deliver a high top speed while still meeting the requirement for a low stalling speed. This was because both the full-length ailerons on both the top and bottom wings could be drooped to act as flaps (what would today be called flaperons) while also having leading edge slats on the upper wing that also decreased stalling speed. The aircraft structure was relatively advanced for its time, with the bottom wing being built as a self-supporting cantilever unit that incorporated the condenser tanks for the Rolls Royce Goshawk engine. The pilot was given a raised seating position with his eye-line at the same level as the top wing for an improved view in the upper hemisphere and down over the nose. So, although it was a biplane, a type of aircraft the Air Ministry had been dead against ordering for F7/30, it did address all the requirements and the Air Ministry agreed to pay for the loan of a Goshawk engine (Rolls-Royce were offering loans of them at a very low price) and 4 machine guns so that Bristol could build a prototype using their own money. During development, the original design of "V" struts for the wings was dropped in favour of "N" struts and the undercarriage design was switched from one with supporting struts and spatted wheels to one with trousered fairings. As originally designed. a thin fuselage would have had large blisters on the side to accomodate the breeches of the machine guns but the fuselage was made wider so that blisters were not required. Like all the other manufacturers who used the Goshawk engine, Bristol had issues getting its cooling system to work and this delayed the building and testing of the prototype. But when it came to actually flying, the Type 123 encountered serious stability problems. One description of the issues encountered says the aircraft just wallowed, uncertain of which direction to point in, obviously not ideal for aiming guns! Efforts to solve this involved increasing the fin and rudder area and clamping the leading-edge slats shut but as one aerodynamic issue was solved others would emerge. Bristols called in the Royal Aircraft Establishment at Farnborough for advice. They concluded that the problem was intrinsic to the design and could not be solved without a complete rebuild. Bristols decided to cut their losses and abandon development of the Type 123, concentrating on their parallel Type 133 monoplane project instead.

An estimation of the form of the early submission of the Bristol Type 123 to the Air Ministry, based on a small, grainy, photo of a model produced by Bristol to show the layout to the Air Ministry (inset). It is likely the project was based on an even earlier layout powered by Bristol's own Mercury radial engine.

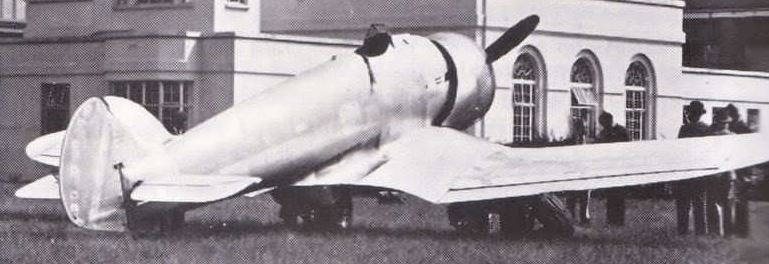

How it turned out: The neat and streamlined Bristol 123 biplane was delayed by engine problems but ultimately scuppered by aerodynamic issues.

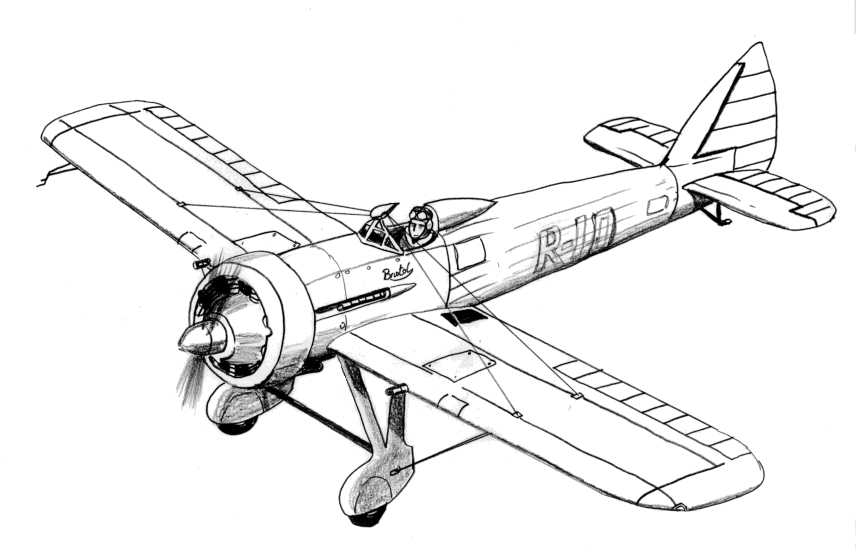

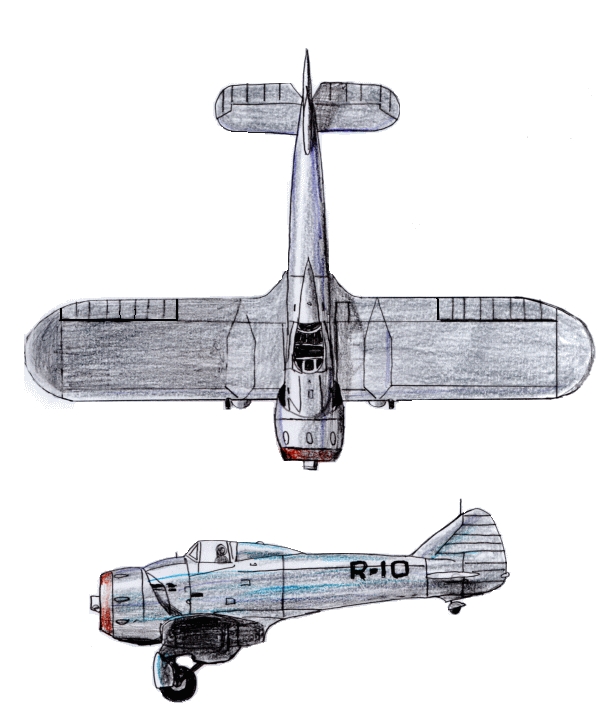

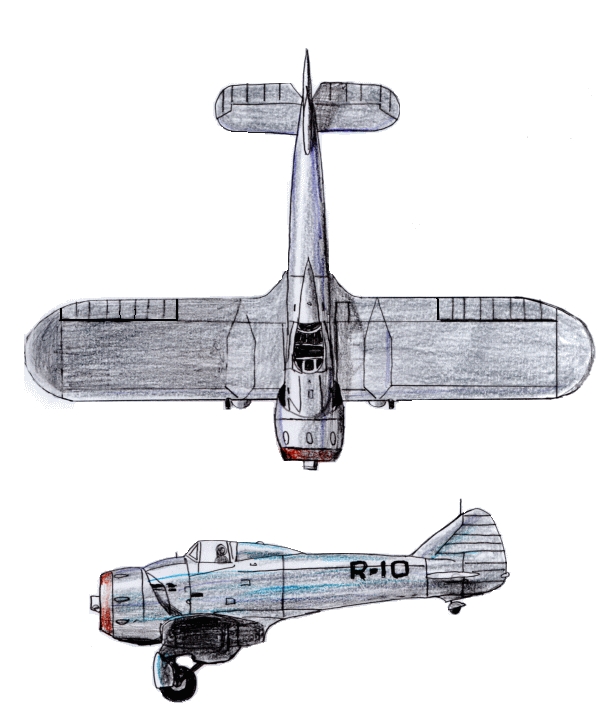

Meanwhile, work on a true cantilever monoplane design, incorporating the stressed skin construction devised by Harry Pollard, was going ahead, designed under the leadership of Frank Barnwell but with the detail design work done by Leslie Frise. An inverted gull-wing of constant cord was adopted, similar in layout to that later used on the famous American Vought F4U Corsair fighter. This allowed the retractable landing gear to be shorter but it was a rather inelegant design that retracted backwards into large fairings at the "knuckle" of the wing, similar to that of the later Seversky P-35 and Gloster F5/34 fighters. It had the advantage that a small portion of the wheel was left protruding which could reduce the damage to the underside of the aircraft in the event of a wheels-up landing or crash. The fuselage was of metal monocoque construction with only the control surfaces being fabric-covered.

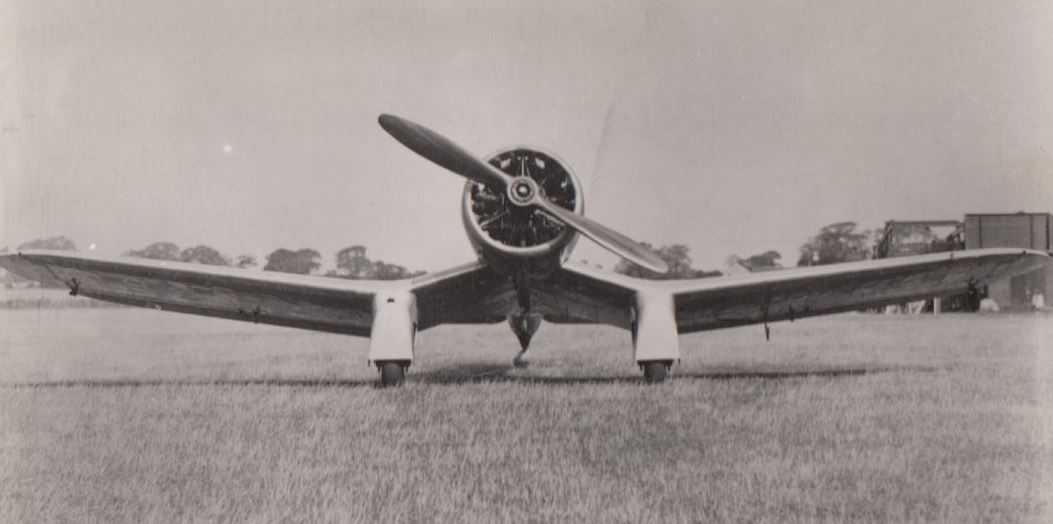

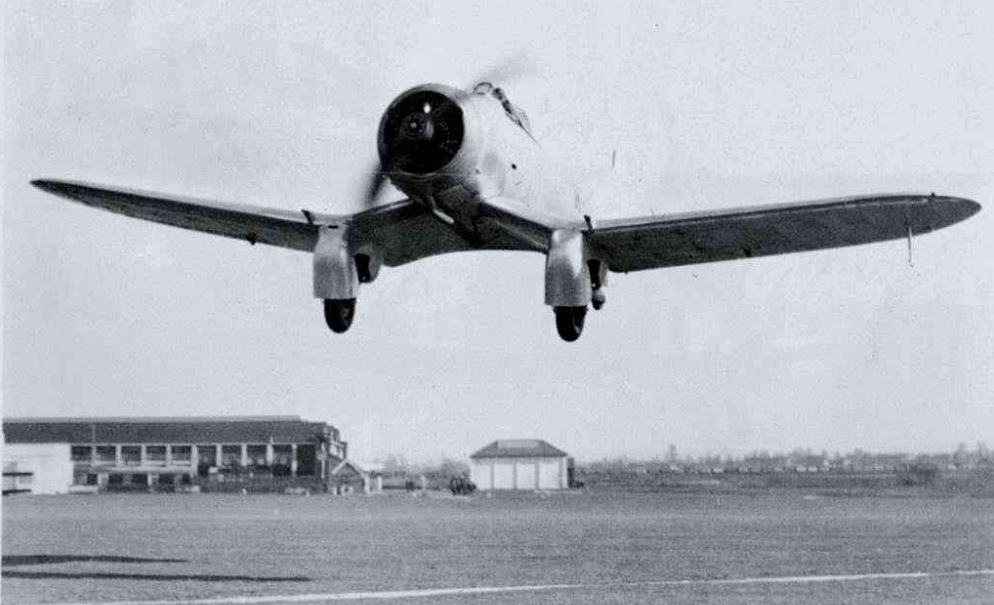

Bristol Type 133 from the front, showing the inverted gull-wing layout

Powered by a Bristol Mercury VIS.2 rated as giving 605 horsepower enclosed in a curiously shaped cowl, driving a two-blade fixed-pitch propeller, the Type 133 initially had an open cockpit and large span ailerons that could be drooped to act like flaps. The armament was two guns in the fuselage, with interrupter gear to be able to fire through the propeller disk and two guns in the wings on top of the undercarriage fairings. The large fairings helped accommodate ammunition. It should be noted that one authorative source, Putnam's "Armament of British Aircraft 1909-1939" by HF King, states, "All four guns were of Vickers type, although it is sometimes stated that those in the wings were Lewis guns". F7/30 specified two Vickers guns in the fuselage with synchronisation gear to fire through the propeller with handles in the cockpit to clear stoppages but left it up to manufacturers to choose between either Vickers or Lewis guns to provide another two weapons in either the fuselage or wings.

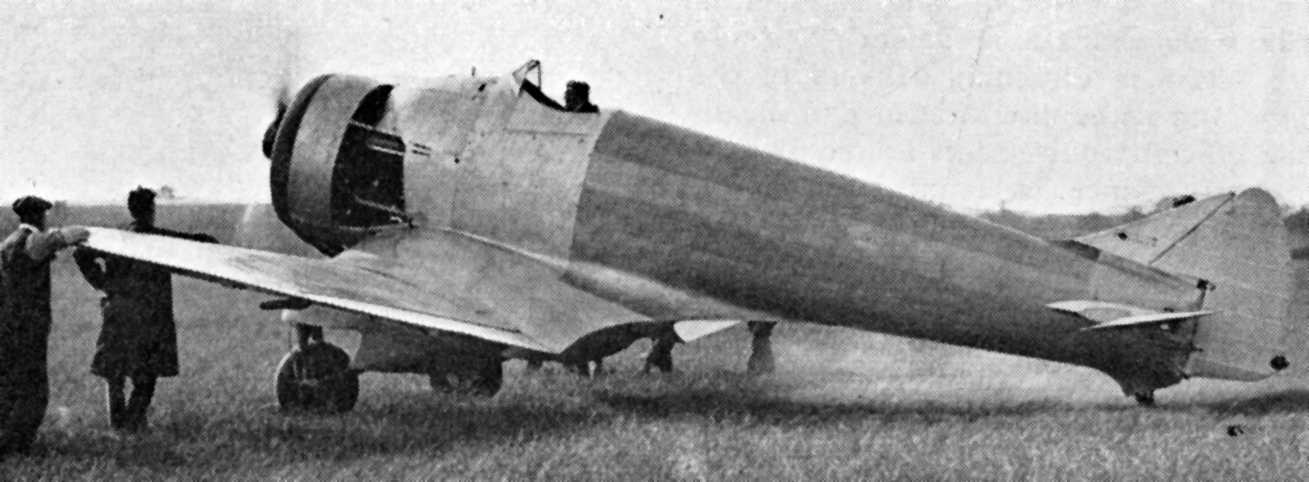

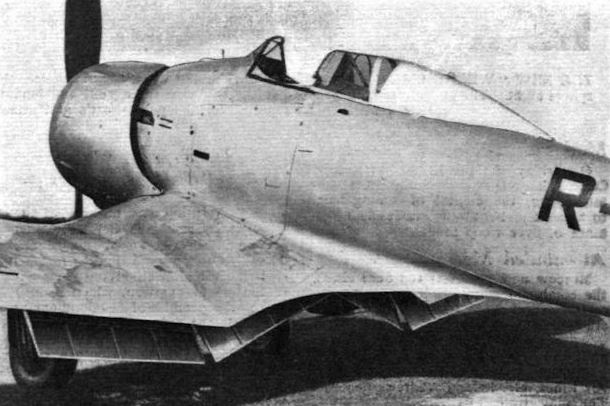

For its early test flights the Bristol 133 flew with the cowling flaps removed. Note the small rudder.

The Type 133 as it was originally built, with an open cockpit. Notice the lack of doors on the undercarriage at this stage.

The prototype 133 was first flown on the 8th of June 1934 by Bristol's test pilot Cyril Uwins who reported it handled well. Over the following months, many improvements were made. A crash pylon was fitted to protect the pilot in case of the aircraft overturning. A fully enclosed cockpit with a sliding hood was fitted. One unusual feature of the canopy was that it did not slide over the fairing behind it instead the fairing and canopy were one unit that slid back together over the top of the fuselage. The brakes were improved and the original tail skid was replaced by a tail wheel. The system of flaperons was removed to be replaced by ailerons and split flaps (then still a novelty). To improve stability the rudder was enlarged with a crudely applied extension, this was soon replaced by a redesigned fin and rudder that was slightly larger and more pointed.

Another view of the prototype before it had the enclosed cockpit fitted. Notice the long-span flaperons on the wings and the way the rudder has been rather crudely enlarged with a section added to its trailing edge.

So, by the beginning of 1935, the Type 133 had assumed the attributes that would typify fighters of World War II, metal stressed-skin construction, enclosed cockpit and retracting undercarriage. This was 5 months before the American Curtiss P-36 first flew, 6 months before the German Bf109, 9 months before the American Seversky P-35, 12 months before the Hurricane (which still had a fabric-covered fuselage) and almost 18 months before the Spitfire. The Type133 prototype had a top speed of only 260 mph, well below the speeds of those other aircraft but it did that with an engine of only 640 horsepower. Later marks of the Mercury, as used on the production Gloster Gladiators, had their power increased to 825 horsepower, so there is every chance that a production Type 133 might have had a considerably greater top speed.

Side view of the Bristol Type 133. Note the "V" section of rudder that formed a horn balance by projecting into the airflow on the opposite side to the action of the rudder. A lot of Bristol designs at the time featured this unusual configuration (for example, see the photo of the Bristol 123 biplane earlier in this webpage) rather than having the usual horn balance position at the top of the rudder.

The Bristol Type 133. Compare this picture with the one above it and you will see that the cockpit canopy does not slide back over the fairing behind it. Instead, they are all one unit that slides back together. If the rear part of the fairing had been made of perspex this would be like the "bubble" canopies that came into use during the last half of WW2.

The Bristol Type 133. Compare this picture with the one above it and you will see that the cockpit canopy does not slide back over the fairing behind it. Instead, they are all one unit that slides back together. If the rear part of the fairing had been made of perspex this would be like the "bubble" canopies that came into use during the last half of WW2.

Another view, showing the split flaps in their down position. The wing was mated to the thin rear fuselage by large fillets. Bristol perhaps missed a trick by not appreciating that a gull wing mated at right angles to a circular section fuselage does not generate interference drag; the F4U Corsair did not require fillets at the wing roots. The prototype Type 133 carried the "B" class registration "R-10" on the fuselage.

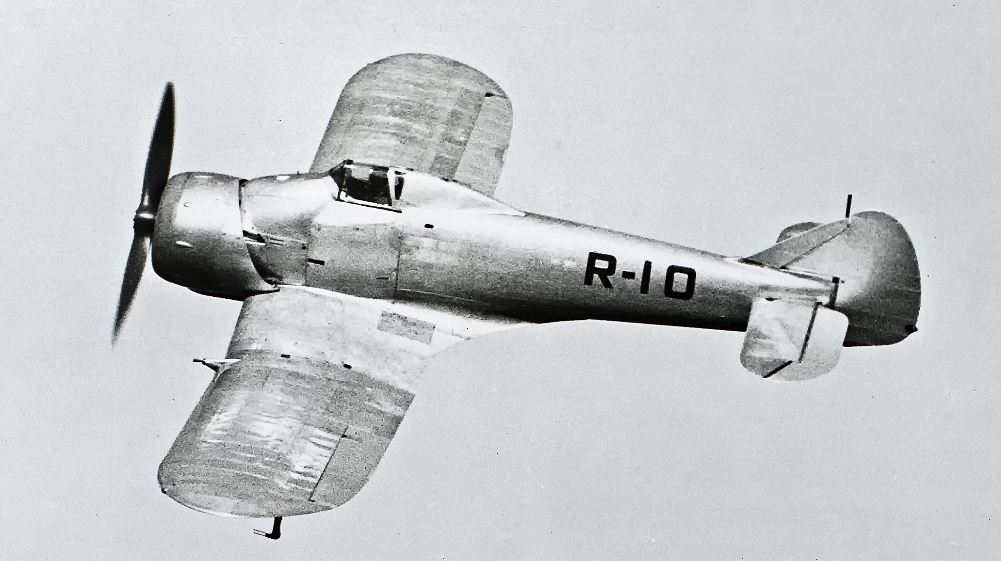

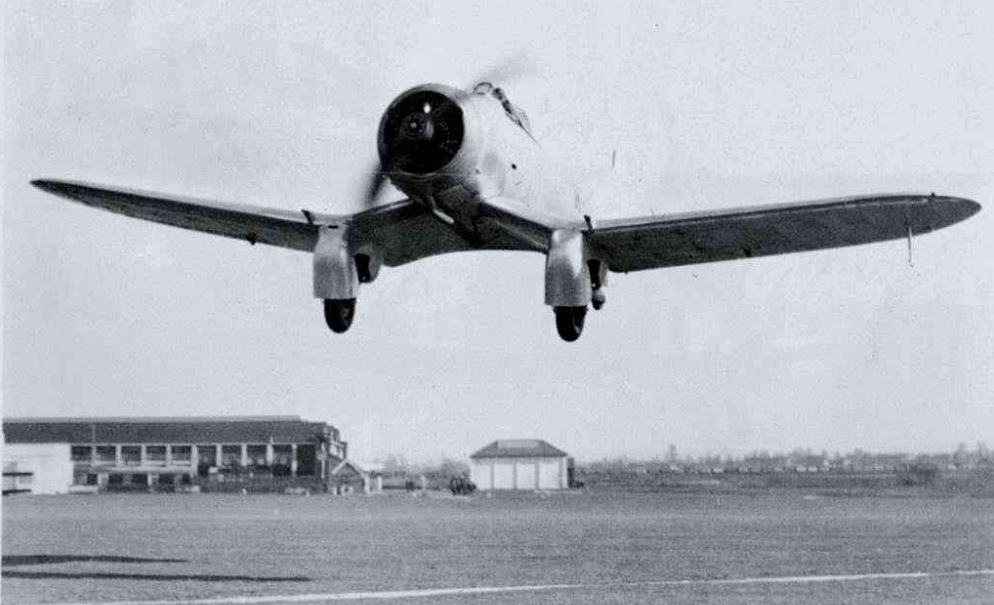

This view of the Type133 in flight makes you appreciate just how large the undercarriage fairings were.

Coming into land, notice the wing machine guns, just outboard of the undercarriage fairings. The placing of the engine exhaust pipe directly under the fuselage would have shielded the pilot from its glare during night flying, essential to meet the day-and-night "zone fighter" aspects of the F7/30 specification.

Another front view of the Bristol Type 133 in flight, showing the inverted gull-wing layout.

A widely reproduced photo of the Type 133 in later configuration with a cockpit canopy, split flaps instead of flaperons and a redesigned fin and rudder. The photo has almost certainly been retouched to make the engine cowling and rudder look more traditional and add a black anti-glare panel in front of the pilot's windscreen.

Bristol Type 133

Max Speed: 260 mph (418 kph). Empty Weight: 3,322 lbs (1,507 kg). All-up Weight: 4,738 lbs (2,149 kg).

Span: 39 feet (11.887 metres). Length: 28 feet (8.534 metres).

Armament: Four Vickers .303 machine guns, two in the fuselage and one in each wing (some sources say Lewis guns were used in the wings).

Provision to carry four 25 lb (11.3 kg) bombs.

Engine: Bristol Mercury VIS.2 radial engine giving 640 hp.

A closer view of the nose and undercarriage.

This view of the Type133 in flight makes you appreciate just how large the undercarriage fairings were.

Coming into land, notice the wing machine guns, just outboard of the undercarriage fairings. The placing of the engine exhaust pipe directly under the fuselage would have shielded the pilot from its glare during night flying, essential to meet the day-and-night "zone fighter" aspects of the F7/30 specification.

Another front view of the Bristol Type 133 in flight, showing the inverted gull-wing layout.

A widely reproduced photo of the Type 133 in later configuration with a cockpit canopy, split flaps instead of flaperons and a redesigned fin and rudder. The photo has almost certainly been retouched to make the engine cowling and rudder look more traditional and add a black anti-glare panel in front of the pilot's windscreen.

Bristol Type 133

Max Speed: 260 mph (418 kph). Empty Weight: 3,322 lbs (1,507 kg). All-up Weight: 4,738 lbs (2,149 kg).

Span: 39 feet (11.887 metres). Length: 28 feet (8.534 metres).

Armament: Four Vickers .303 machine guns, two in the fuselage and one in each wing (some sources say Lewis guns were used in the wings).

Provision to carry four 25 lb (11.3 kg) bombs.

Engine: Bristol Mercury VIS.2 radial engine giving 640 hp.

A closer view of the nose and undercarriage.

The prototype had passed all its manufacturer's tests (including spinning tests) and was due to go to Martlesham Heath for evaluation by A&AEE. Before it went, one of Bristol's staff pilots (the chief instructor at Bristol's flying school at Filton), Thomas "Jock" Campbell, took it up for a quick flight (on the 8th of March 1935). He did a full set of aerobatic tests and made an approach to land, including extending the undercarriage, when he decided he still had time to test the type's spinning characteristics. So he climbed back up to do that. Unfortunately, he forgot to retract the undercarriage and when he put the aircraft into a deliberate spin at 14,000 feet (4,267 metres) the drag of the undercarriage made the spin tighten up and turned it into a flat spin, from which he could not recover by normal means. Additionally, the centrifugal force of the spin starved the engine of fuel and it cut out (at the time, applying full throttle was often used to break out of a spin, something usually discouraged today). Losing height rapidly, Campbell had no option but to bale out, but his foot got caught in the cockpit and he only came free some 2,000 feet (600 metres) above the ground, giving him just enough time to deploy his parachute. The Type 133 smashed into the edge of an orchard near Longwell Green some 6.5 miles (approx 10.5 km) from Bristol's Filton airfield and caught fire.

The remains of the Bristol Type 133 in the orchard at Longwell Green.

With no aircraft to send for evaluation, chances of winning the contract evaporated. The prototype of both the Hawker Hurricane and Supermarine Spitfire had already been ordered, both promising substantial performance increases over the Bristol 133. Although Bristol would go on to design and build another Mercury-engined fighter (hoped to be upgraded to a Perseus engine), the Type 146. This time they would play it safe by starting to build two prototypes! Although, when it became obvious that the aircraft had no realistic chance of winning a production order, the second prototype was scrapped.

The Bristol 146 fighter; with the company preoccupied with Blenheim production, development of it was delayed, and only one of the two prototypes was completed. Its performance was inferior to both the Hurricane and Spitfire, with a maximum speed of only 287 mph at 15,000 feet (462 kph at 4,572 metres).

Another view of the Bristol 146. It was written off after taxying into a static display during an airshow at Bristol's Filton airfield in 1938.

Another view of the Bristol 146. It was written off after taxying into a static display during an airshow at Bristol's Filton airfield in 1938.

So, who actually "won" specification F7/30? Nominally it was the Gloster Gladiator, the RAF's last biplane fighter; although, as already mentioned, its predecessor the Gauntlet, had been the first to combine the role of interceptor and zone fighter and it was Gauntlets that largely replaced Bristol Bulldogs in front-line squadrons. Of the various contenders for F7/30, only three were actually paid for by the Air Ministry and must be considered the front-runners for orders. The first of these was the

Blackburn F3, a biplane, but a biplane of so wacky a configuration that you can imagine the Air Ministry thinking "We've just got to see if this would work". It didn't, and the Air Ministry withdrew support. The next was the equally wacky Westland F7/30, this started as a monoplane design with the engine behind the pilot driving a propeller through an extension shaft, like the later American P-39 Airacobra. You can see why the Air Ministry would have wanted to see if this design worked. However, Westland then decided that to meet the landing speed they would have to convert it into a biplane. When built, the Westland F7/30 did not even reach the modest 195 mph goal set by the specification. The last of the Air Ministry favourites, and the front-runner because of the reputation of its designer, R.J. Mitchell, was the Supermarine Type 224. This was a fixed undercarriage, inverted gull-wing, Goshawk-powered monoplane. However, even before it was close to flying Mitchell approached the Air Ministry and effectively said "I can do better than this". He proposed fitting a retracting undercarriage and flaps. Air Marshall Dowding is recorded as complaining that he should have done that in the first place! However, the Air Ministry seized on this new proposition. They thought it would be unfair to the other companies tendering for F7/30 to just simply give Supermarine more money to carry out the changes, so they wrote up a whole new, very short specification around Supermarine's proposal, F37/34. This was for an experimental aircraft, so it did not have to go out to general tender to the whole aircraft industry, it was strictly Supermarine's baby, and the Air Ministry agreed to fund its building in full. The oft-repeated myth that the Spitfire was a "private venture" with no Air Ministry support was fostered by the Vickers-Supermarine Chairman, Sir Robert McLean. The very first paragraph of F.37/34 reads: "The aircraft shall conform to all the requirements stated in Specification F7/30."

So, in a way, the Spitfire was the winner of F7/30.

What If?

Bristol Type 133 painted as if it had gone into production and service, with the serial and markings worn by a Gladiator of No 87 Squadron.

If the Bristol Type 133 had been selected for production instead of the Gladiator, its slight edge in speed might have made it very welcome in the Middle East, over Italian East Africa and in the early stages of the British involvement in Greece where its principle opponents would have been Italian CR32 and CR42 biplanes. It would have also given British and Commonwealth pilots early experience in handling higher-performance monoplane fighters. However, there is also the possibility that having a monoplane in service would have lulled the Air Ministry into a false sense of security and maybe there would have been less importance given to developing the Hurricane and Spitfire. Perhaps the Hurricane would not have been ordered at all, which would have left the RAF at a serious disadvantage against the German Bf109. Although the Type 133 would have benefited from the boost in power of later marks of Mercury engine and might have also profited from variable pitch and constant-speed propellers to perhaps approach top speeds of 280 or 290 mph, it would not have had the firepower or longer-term development potential of the Hurricane. One tantalising aspect of the Bristol 133, at least in its prototype form, was an exceptionally low wing-loading for a monoplane fighter of only 19 pounds per square foot. That is substantially lower than the Japanese Zero or Oscar fighters which both relied on their amazing manoeuvrability in combat. Might the Bristol Type 133 have surprised Japanese pilots in turning fights? Or would the additional weight of armour protection and extra equipment have robbed the Type 133 of this possible advantage?

Although probably a poor match for German Bf109 fighters in Europe, the Bristol 133 might have been of great use against Italian CR32 and CR42 biplane fighters in the Western Desert and over Italian East Africa in the first year of the war against Italy.

NOTES

¹ A full copy of the complete Air Ministry F7/30 specification can be found in "Spitfire - The History" by EB Morgan and Edward Shacklady. It is in Appendix III (pages 597-601 in the 2000 edition).

² For an understanding of these events see “That Ban – The Outlawing of Monoplanes, 1912” – An article by Paul R. Hare in Air Enthusiast magazine, issue 104 March/April 2003. There is another article on this website that covers the issue, at <this link>.

LINKS

SOURCES

"Bristol Aircraft since 1910": by CH Barnes, published by Putnam. ISBN : 0 85177 823 2.

"Spitfire - The History": By Eric Morgan and Edward Shacklady, 5th edition published in 2000 by Key Books. ISBN: 0 946219 48 6. This massive book has an excellent prologue chapter that covers all the designs for F7/30. The appendix in the 5th edition onwards contains a complete copy of the entire Air Ministry F7/30 specification. This corrects the mistaken outline of the specification in the same author's article on F7/30 in issue No 10 of "Twentyfirst Profile" magazine in 1991 and "The British Aircraft Specification File" (see below).

"The British Aircraft Specification File" - By K. Meecome and Eric Morgan. Published by Air-Britain in 1994. ISBN 0 85130 2220 3. This very authorative book actually has a erronious entry for F7/30, claiming it required a top speed of 250 mph. However, you'll see that one of its authors is Eric Morgan, who later went out of his way to put the record straight about the true nature of F7/30 from further research he did for the 5th edition of his "Spitfire" book. It does have a proper listing for 14/35, classifying as a production order for the Gloster Gladiator.

"The Bristol Types 123 and 133": an article by "Senrab" in the June 1958 edition of "Air Pictorial" magazine.

"The RAF and Aircraft Design 1923-1939": By Colin Sinnott, published by Frank Cass. ISBN 0 7146 5158 3. It is a brilliant source that deserves to be more widely read. The book presents a picture of the Air Ministry, in the late 1920s and early 1930s, being exasperated by the British aviation industry repeatedly offering biplane designs. Moreover, they found it even more frustrating that when British monoplanes were designed and tested, they often performed worse than the biplanes.

"A Span of Wings - An Autobiography": By Sir Archibald Russell. Published by Airlife Publishing Ltd, 1992. ISBN 1 85310 234 2. Archibald Russell started working in the design office of Bristols in 1925, doing calculations on aircraft structures. So he had a front row view of the development of the Type 133. He worked his way up through the company, ending up as managing director of the British Aircraft Corporation.

"The Journal of the Royal Air Force Historical Society" had an issue devoted to the Bristol Aircraft Company. The article on aircraft design and construction by Peter Coombs covers the development of stressed-skin construction. The journal can be accessed at <this link>.

"The Gloster Gauntlet": A Profile Publication by Francis K Mason. It briefly covers how the Gloster SS18 design progressed through to the SS19 "multi-gun fighter" with 6 machine guns. Then the Air Ministry realised that the weight saved by removing four of the machine guns would allow the fitting of radio and night-flying equipment to produce an aircraft that could perform the day-and-night "zone fighter" task while having the same speed and climb as the "interceptor class" Hawker Fury. This resulted in the SS19B Gauntlet.

"Armament of British Aircraft - 1909 -1939": By H.F. King, published by Putnam in 1971. ISBN: 0 370 00057 9. It has a brief, one-paragraph mention of the Bristol 133. It states that the prototype had four Vickers guns rather than the two Vickers guns and two Lewis guns in the wings the type is usually credited as carrying. H.F. King served as an RAF technical officer specialising in armament during WW2 and as a technical writer and editor for "Flight" magazine in the 1930s.